The selection of overhead crane hook involves several critical standards and characteristics, each addressing different aspects of the hook’s performance, safety, and durability. These considerations include load capacity, material choice, design features, and working environment, among others.

1. overhead crane hook Rated Load

- Selection Standard: The rated load of the hook should align with the rated lifting capacity of the crane. It is essential that the hook’s rated load matches the crane’s maximum working load.

- Characteristics: A hook with a capacity that is too large can compromise its strength, while one that is too small can decrease lifting efficiency and may even pose safety risks. Therefore, it’s crucial to choose a hook that matches the lifting requirements.

2. overhead crane hook Working Environment

- Selection Standard: The choice of hook must consider the specific environmental conditions such as temperature (whether high or low), humidity, corrosive environments, and exposure to chemicals. In high-temperature environments, heat-resistant steel may be necessary, while in corrosive settings, stainless steel or surface treatments should be considered.

- Characteristics: The material selection and surface treatment depend heavily on the environment. For instance, hooks used in marine environments need special corrosion-resistant coatings, whereas those in extreme temperature conditions must be made from materials capable of withstanding temperature fluctuations.

3. Material of the Hook

- Selection Standard: The hook material should provide sufficient strength, toughness, and wear resistance. Common materials include carbon steel, alloy steel, and stainless steel. The material must balance both weight and strength to meet the safety requirements of lifting operations.

- Characteristics: Alloy steel hooks offer better toughness and wear resistance but may be heavier than carbon steel. Stainless steel hooks, on the other hand, are ideal for corrosive environments due to their strong resistance to rust and longer service life.

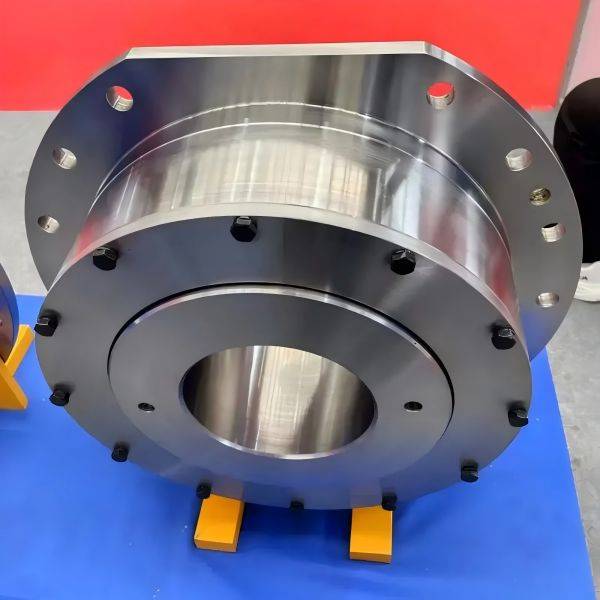

4. Hook Body Design

- Selection Standard: The hook design should meet the specific lifting requirements, ensuring the hook’s strength, stability, and safety. Hook designs vary, with single, double, or triple hooks available. The throat opening and hook body shape must be carefully designed to prevent loads from slipping off during lifting.

- Characteristics: The design must avoid stress concentrations to prevent deformation or failure. It must also account for load distribution and ensure stable lifting without unexpected accidents.

5. Safety Factor

- Selection Standard: The safety factor is a crucial parameter in hook selection, determining the ratio between the hook’s maximum load capacity and the actual working load. The typical safety factor is between 5 and 6, depending on specific conditions.

- Characteristics: A higher safety factor provides greater safety, especially in case of unexpected overloads, but excessively high safety factors may lead to unnecessarily heavy hooks, reducing lifting efficiency.

6.overhead crane hook Throat Design

- Selection Standard: The throat design should ensure the load is securely attached, preventing accidental detachment. The opening size must match the dimensions and shape of the lifted item.

- Characteristics: The throat opening should be slightly larger than the load to ensure a secure fit, preventing the load from becoming unstable or detached during lifting.

7. Overload Protection and Prevention of Hook Drop

- Selection Standard: The hook should incorporate overload protection, such as overload indicators or limit switches, to prevent excessive loads. Additionally, a hook may be designed with an anti-drop mechanism to reduce the risk of the load falling off.

- Characteristics: Overload protection devices prevent damage to the hook or load due to overloading. Anti-drop features ensure the load remains secure, especially in high-speed or vibration-prone environments.

8. Operational Performance

- Selection Standard: The hook should demonstrate smooth rotation, stability, and wear resistance to ensure reliable operation during frequent lifting tasks.

- Characteristics: A hook with excellent operational performance reduces the likelihood of malfunctions, such as jamming or malfunctioning, which would decrease operational efficiency. The material’s wear resistance and the surface finish directly influence the ease of operation.

9. Maintenance and Inspection

- Selection Standard: The hook should be designed for easy inspection and maintenance. Regular checks for wear, cracks, and deformation should be possible to ensure the hook’s safety during long-term use.

- Characteristics: A hook that is easy to maintain reduces downtime and extends its service life. Timely inspections and repairs can prevent potential safety hazards, ensuring continuous, safe operation.

10. Compliance with Standards

- Selection Standard: The design and manufacturing of the hook must comply with relevant national and international standards, such as GB/T 3811, GB/T 3810, or international standards like ISO 4301. These standards guarantee the hook’s quality and safety.

- Characteristics: Hooks that comply with these standards undergo strict testing and verification, ensuring they are reliable and safe for use in various lifting operations.

11. Corrosion Resistance and Surface Treatment

- Selection Standard: The hook should undergo appropriate surface treatments, such as painting, galvanizing, or heat treatment, depending on the working environment. Special corrosion-resistant coatings are especially necessary in marine or chemical environments.

- Characteristics: Corrosion-resistant treatments greatly extend the hook’s service life and reduce the likelihood of damage from environmental exposure, ensuring long-term stability of lifting operations.

overhead crane hook Summary:

In conclusion, selecting an overhead crane hook is a comprehensive process that requires considering several factors, including load capacity, material, design, working environment, maintenance, and safety standards. By carefully choosing the right hook, one can ensure efficient lifting operations, enhance safety, and prolong equipment lifespan.