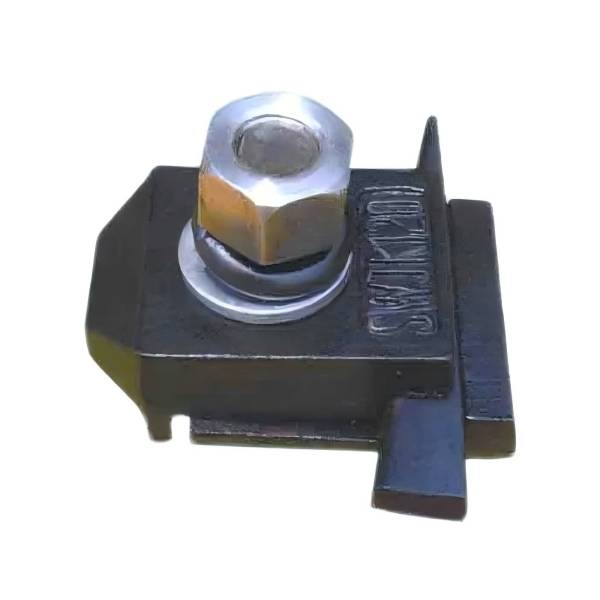

SWJK Rail Clip

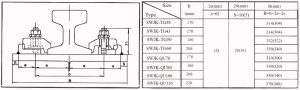

Specifications of SWJK Rail Clip

- Models: SWJK-TG38, SWJK-TG43, SWJK-TG50, SWJK-TG60, SWJK-QU70, SWJK-QU80, SWJK-QU100, SWJK-QU120

- Fixing Method: Welded base plate

Features of SWJK Rail Clip

The SWJK rail clip is specifically designed for applications that require specialized pressing plates. While maintaining the core design principles of the WJK rail clip, the SWJK rail clip incorporates modifications to meet unique operational requirements and environmental conditions.

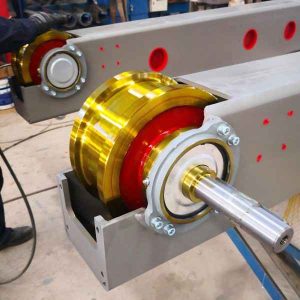

Welding and Installation

The SWJK rail clips utilize a three-side surrounding welding method for installation, with a weld seam height of 7mm. This design choice ensures a secure and stable attachment to the base plate, allowing the clip to reliably withstand the stresses and forces applied during operation.

Material Specifications

For SWJK clips made from Q345 material, the tightening torque is set at 150N·m. These clips are built to endure a maximum lateral force of 40kN at each wheel pressure point. Furthermore, they can withstand a maximum horizontal force of 25kN under guided wheel conditions, ensuring robust performance even under heavy-duty operational conditions.

Customization Options

For projects with specific requirements or situations where the height clearance between the crane’s horizontal wheel and the crane beam is minimal, it is recommended that users notify the manufacturer in advance. This will allow the manufacturer to provide tailored adjustments to ensure optimal functionality for the particular installation.

Through these thoughtful design modifications, the SWJK rail clip provides enhanced performance and versatility, effectively addressing the unique needs of specialized applications while maintaining the reliability and durability of the original WJK rail clip.