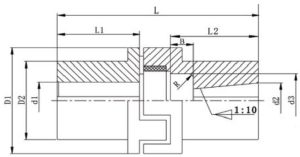

Plum blossom elastic coupling

ML Plum Blossom Elastic Coupling Parameters:

- Maximum allowable torque: 630 Nm to 125,000 Nm

- Maximum speed: 1,350 r/min to 15,300 r/min

- Shaft hole diameter: ∅12 to ∅200

- Custom non-standard sizes: Available based on provided drawings, with manufacturing according to the dimensions on the drawings.

The parameters and dimensions of the ML Plum Blossom Elastic Coupling

| Type | Nominal torque | Permissible speed | Shaft hole diameter d1 ,d2 |

Shaft hole length:L1,L2 | L | D1 | D2 | B | D3 | R | Elastic parts type | Weight | Moment of Inertia |

| N.m | r/min | mm | mm | mm | kg | kg.m² | |||||||

| ML1 | 25 | 15300 | 12.14 | 32 | 80 | 50 | 40 | / | / | / | MT1-b | 1.22 | 0.00026 |

| 16,18,19 | 42 | 100 | |||||||||||

| 20,22,24 | 52 | 120 | |||||||||||

| ML2 | 100 | 10900 | 20,22,24 | 52 | 127 | 70 | 48 | / | / | / | MT2-b | 2.9 | 0.001 |

| 25,28 | 62 | 147 | |||||||||||

| 30,32 | 82 | 187 | |||||||||||

| ML3 | 140 | 9000 | 22,24 | 52 | 128 | 85 | 60 | / | / | / | MT3-b | 4.33 | 0.0023 |

| 25,28 | 62 | 148 | |||||||||||

| 30,32,35,38 | 82 | 188 | |||||||||||

| ML4 | 250 | 7300 | 25,28 | 82 | 151 | 105 | 72 | 14 | 38 | 1.5 | MT4-b | 7.78 | 0.0063 |

| 30,32,35,38 | 62 | 191 | |||||||||||

| 40,42 | 82 | 251 | |||||||||||

| ML5 | 400 | 6100 | 30,32,35,38 | 112 | 197 | 125 | 90 | 18 | 48 | 1.5 | MT5-b | 11.72 | 0.015 |

| 40,42,45,48 | 82 | 257 | |||||||||||

| ML6 | 630 | 5300 | 35,38, | 112 | 203 | 145 | 104 | 22 | 65 | 2 | MT6-b | 14.83 | 0.027 |

| 40,42,45,48,50,55 | 112 | 263 | |||||||||||

| ML7 | 1120 | 4500 | 45,48,50,55 | 112 | 265 | 170 | 110 | 28 | 80 | 2 | MT7-b | 26.69 | 0.061 |

| 60,63,65 | 142 | 325 | |||||||||||

| ML8 | 1800 | 3800 | 50,55, | 112 | 272 | 200 | 135 | 28 | 95 | 2.5 | MT8-b | 40.57 | 0.13 |

| 60,63,65,70,71,75 | 142 | 332 | |||||||||||

| ML9 | 2800 | 3300 | 60,63,65,70,75 | 142 | 334 | 230 | 160 | 35 | 105 | 2.5 | MT9-b | 65.2 | 0.274 |

| 80.85.90.95 | 172 | 394 | |||||||||||

| ML10 | 4500 | 2900 | 70,71.75 | 142 | 344 | 262 | 180 | 40 | 140 | 2.5 | MT10-b | 101.6 | 0.53 |

| 80.85.90.95 | 172 | 404 | |||||||||||

| 100,110 | 212 | 484 | |||||||||||

| ML11 | 7100 | 2500 | 80,85,90,95 | 172 | 411 | 300 | 200 | 40 | 160 | 3 | MT11-b | 131.2 | 0.963 |

| 100,110,120 | 212 | 491 | |||||||||||

| ML12 | 11200 | 2100 | 90,95 | 172 | 417 | 360 | 225 | 45 | 210 | 3 | MT12-b | 200.4 | 2.091 |

| 100,110,120,125 | 212 | 497 | |||||||||||

| 130 | 252 | 577 | |||||||||||

| ML13 | 12500 | 1900 | 100,110,120,125 | 212 | 497 | 400 | 225 | 50 | 235 | 4 | MT13-b | 247.6 | 3.19 |

| 130,140 | 252 | 577 | |||||||||||

| ML14 | 20000 | 16550 | 110,120,125 | 212 | 499 | 460 | 260 | 50 | 265 | 4 | MT14-b | 292 | 5.95 |

| 130.140.150 | 252 | 579 | |||||||||||

| ML15 | 25000 | 1500 | 120.125. | 212 | 504 | 500 | 300 | 60 | 310 | 5 | MT15-b | 355 | 9.62 |

| 130.140.150 | 252 | 584 | |||||||||||

| 160,170,180 | 302 | 684 | |||||||||||

| ML16 | 31500 | 1350 | 130,140,150 | 250 | 584 | 550 | 340 | 70 | 330 | 5 | MT16-b | 405 | 12.71 |

| 160,170,180 | 302 | 684 | |||||||||||

| 190,200 | 252 | 784 | |||||||||||