Overhead Crane Hook

Overhead crane hook parameters:

- Specifications: 3.2t, 5t, 10t, 16t, 20t, 32t, 50t, 75t, 100t, 125t, 160t, 200t, 320t, 400t, 500t

- Working level: M3, M4, M5, M6, M7, M8

- Hook material: DG20, DG20Mn, 35CrMo

- Pulley cover type: semi-enclosed, fully enclosed

- Hook type: single hook, double hook, laminated hook

The overhead crane hook is a critical component of an overhead crane system, used primarily for lifting and carrying loads. It serves as the interface between the crane’s hoisting mechanism and the load being lifted. The hook is typically attached to the lifting rope or chain and is designed to securely hold the load during lifting, lowering, and transportation. Overhead crane hooks are used in a wide range of industries, including manufacturing, construction, shipping, and warehouses, where heavy loads need to be moved efficiently and safely.

Key Features of Overhead Crane Hooks

- Load Capacity:

Overhead crane hooks are designed to handle a variety of loads, ranging from light to extremely heavy, depending on the size and specifications of the crane. The hook must be able to withstand high stresses and forces during lifting operations without failing. - Material:

The hook is usually made from high-strength steel or alloy materials that provide durability and resistance to wear and tear. These materials ensure that the hook can perform under harsh working conditions, such as in high-temperature environments or when lifting corrosive materials. - Shape and Design:

The hook is typically designed with a curved shape to prevent the load from slipping off during lifting. The opening at the tip of the hook is often equipped with a safety latch or latch mechanism to secure the load and prevent accidental release. Some hooks also feature an additional safety feature, such as a swivel function, which allows the hook to rotate freely without twisting the load’s lifting line. - Safety Features:

Many overhead crane hooks are equipped with safety mechanisms, such as a safety latch or locking mechanism, to ensure the load remains secure during the lifting process. The safety latch prevents the load from accidentally detaching, even if the crane hook swings or is subject to sudden movements. - Swivel Hooks:

Some overhead crane hooks come with a swivel feature, allowing them to rotate freely around their axis. This feature can help prevent twisting of the lifting rope or chain and makes handling more flexible, especially when lifting irregularly shaped loads. - Customization:

Overhead crane hooks can be customized based on the application and specific load requirements. For example, they can be designed with different types of hooks, such as single hooks, double hooks, or specialized hooks for specific industries, including those with magnetic lifting capabilities or designed to handle specific materials like coils or plates.

Applications of Overhead Crane Hook

Overhead crane hooks are used in various applications where heavy lifting is required, such as:

- Manufacturing: In factories, they are used to lift heavy equipment, machinery, and components.

- Construction: Overhead crane hooks are essential for lifting construction materials, steel beams, and other heavy components during building projects.

- Warehouses: In warehouses, crane hooks are often used to move large pallets, storage containers, or bulky goods.

- Shipping Ports: They are used for loading and unloading large cargo from ships, such as containers and industrial equipment.

In conclusion, the overhead crane hook is a crucial component that ensures safe and efficient load handling. Its design, material, and safety features make it an indispensable tool in heavy lifting operations across various industries.

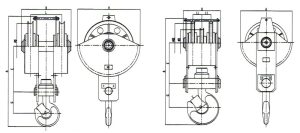

3.2t/5t 10t

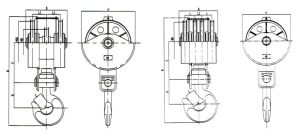

16t 20t/32t

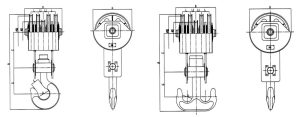

50t 75t

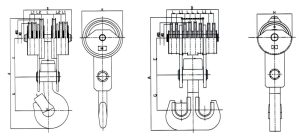

100t 200t

|

Specs |

Mandmensions(mm) | Wire rope parameters | Weight (kg) |

||||||||||||

| A | B | H | E | G | L | L1 | L2 | C | U | ØD1 | ØD | Diameter(mm) | Number | ||

| 3.2 | 775 | 350 | 420 | 320 | 150 | 220 | / | / | 50 | 65 | / | 300 | 11-14 | 4 | 80 |

| 5 | 858 | 370 | 480 | 320 | 184 | 240 | / | / | 65 | 85 | / | 350 | 11-14 | 4 | 100 |

| 10 | 1080 | 378 | 410 | 410 | 243 | / | 92 | / | 90 | 120 | 380 | 250 | 11-14 | 6 | 200 |

| 16 | 1330 | 506 | 485 | 485 | 307 | / | 172 | / | 115 | 150 | 500 | 310 | 14-20 | 6 | 330 |

| 20 | 1415 | 524 | 510 | 510 | 333 | 136 | 93 | / | 130 | 170 | / | 500 | 16-20 | 8 | 460 |

| 32 | 1740 | 604 | 620 | 620 | 420 | 155 | 105 | / | 160 | 210 | / | 610 | 18-22 | 8 | 845 |

| 50 | 1965 | 750 | 710 | 710 | 510 | 170 | 109 | / | 205 | 270 | 710 | 610 | 20-22 | 10 | 1500 |

| 75 | 2335 | 970 | 930 | 930 | 600 | 185 | 135 | / | 250 | 320 | 800 | 500 | 26-32 | 10 | 2500 |

| 100 | 3130 | 1360 | 1100 | 1100 | 955 | 350 | 131 | 200 | 270 | 355 | 1000 | 800 | 28-34 | 12 | 4200 |

| 200 | 3548 | 1617 | 1185 | 1185 | 1298 | 159 | 264 | / | / | 340 | 900 | 800 | 30-38 | 16 | 9100 |