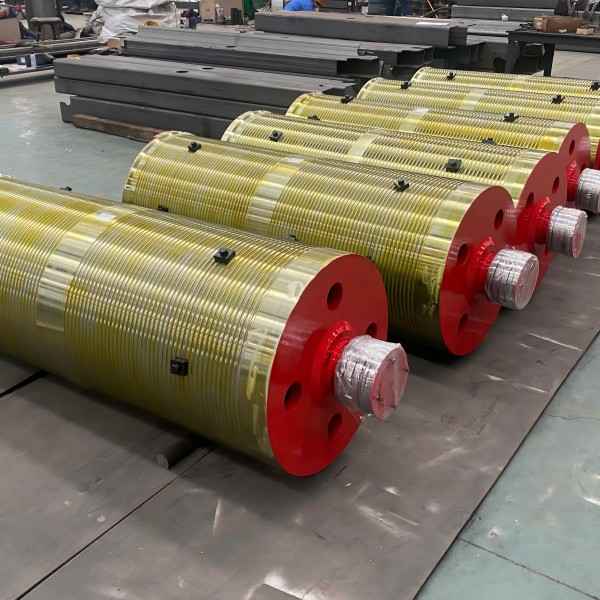

Overhead crane drum

Parameters of overhead crane drum:

- Specifications: Φ300×1000, Φ400×1500, Φ500×1500, Φ650×2000, Φ800×2000, Φ800×3600, Φ1000×3600

- Pulley Material: HT200, Q235B, Q355B,Q355E

- Drum connection: C-type gear plate, WZL drum coupling

- Drum manufacturing process: casting, steel plate rolling, seamless steel pipe

- Drum groove size: determined by the diameter of the wire rope

- Non-standard Customization: We can manufacture according to drawings provided by you

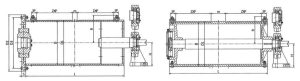

WZL type drum C type drum

| D×L | Drawing No. | Drum coupling | Lifting capacity (t) |

Lifting height (m) | D1 | D2 | D3 | m | P | R | S | H | Reducer |

| Φ400×1000 | TW1022A | WZL05 | 5 | 15 | 409 | 510 | 460 | 48 | 16 | 248 | 16 | 210 | QJYD3-225 |

| TW1028A | QJS-D280 | ||||||||||||

| Φ400×1500 | TW1023A | WZL05 | 5/10 | 22/16 | 409 | 510 | 460 | 150/50 | 16 | 248 | 16 | 210 | QJYD3-225 |

| TW1029A | QJS-D280 | ||||||||||||

| φ500×1500 | TW1024A | WZL06 | 16/20 | 16/12 | 512 | 640 | 580 | 120 | 20 | 316 | 20 | 260 | QJYD3-280 |

| TW1030A | WZL07 | QJRS-D400 | |||||||||||

| φ650×2000 | TW1025A | WZL09 | 32 | 17 | 664 | 810 | 750 | 150 | 24 | 402 | 24 | 360 | QJYD3-400 |

| TW1031A | QJRS-D500 | ||||||||||||

| φ800×2000 | TW1027A | WZL10 | 50 | 12 | 816 | 960 | 900 | 350 | 28 | 478 | 26 | 420 | QJYD3-450 |

| TW1032A | QJRS-D560 | ||||||||||||

| φ800×3600 | TW505A | WZL11 | 75 | 20 | 816 | 950 | 890 | 450 | 34 | 498 | 30 | 420 | QJYD3-500 |

| TW1033A | QJRS-D630 | ||||||||||||

| φ1000×3500 | TW632A | WZL12 | 100/125 | 20 | 1020 | 1200 | 1100 | 300 | 36 | 595 | 34 | 530 | QJYD3-560 |

| TW1034A | QJRS-D710 |