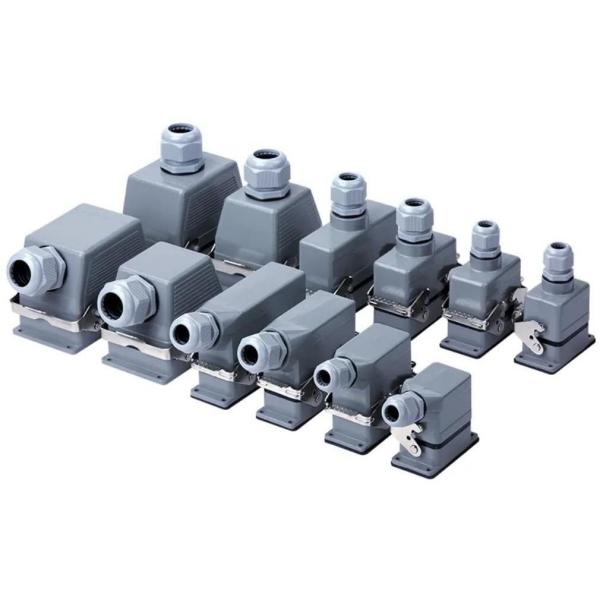

Heavy Duty Aviation Connector

The HE Heavy Duty Aviation Connector, also known as the aviation plug or quick connector, is a versatile and robust solution for electrical and signal connections in industrial equipment, including cranes.

Features and Specifications of Heavy Duty Aviation Connector

Features

- High Strength and Durability:

- Heavy duty aviation connector are made from high-strength materials, offering excellent abrasion resistance, corrosion resistance, and shock resistance. These connectors are designed to withstand mechanical impacts and vibrations, making them ideal for harsh environments and industrial applications.

- Waterproof and Dustproof:

- These connectors have a high protection rating, usually IP67 or higher, effectively preventing the ingress of water, dust, and other contaminants. As a result, they ensure reliable operation in environments with high humidity or a lot of dust.

- Reliable Electrical Performance:

- Heavy-duty aviation connectors provide high current transmission capabilities, ensuring stable power transfer under high load conditions. The contact components are typically made of high-conductivity materials (such as copper alloy), which guarantees reliable and long-lasting electrical connections.

- High and Low Temperature Resistance:

- These connectors are designed to operate in extreme temperatures, usually ranging from -55°C to +200°C. They are well-suited for industries like aerospace, military, and railways, where high or low temperature conditions are common.

- Variety of Connectors:

- Heavy duty aviation connector support various types of connector styles, including circular, rectangular, straight-plug, and detachable types, meeting different application scenarios and requirements.

- Quick Installation and Disconnection:

- These connectors are designed for convenience, with quick connection and disconnection mechanisms that improve operational efficiency. Many models feature self-locking mechanisms, ensuring stable and reliable connections.

- Wide Range of Applications:

- These connectors are widely used in aerospace, military, railway, heavy machinery, industrial equipment, and other fields that require high-strength electrical connections.

Specifications

- Rated Current:

- The rated current range typically varies from 10A to 500A, depending on the connector model and specifications.

- Rated Voltage:

- The rated voltage generally ranges from 250V to 3000V, catering to the electrical demands of various applications.

- Contact Resistance:

- The contact resistance is typically below 1mΩ, ensuring low-resistance connections and reducing energy loss.

- Operating Temperature Range:

- The standard operating temperature range is from -55°C to +200°C, with some models capable of supporting even higher temperatures.

- Protection Rating:

- The protection rating typically meets or exceeds IP67, providing excellent waterproof and dustproof protection.

- Insertion/Withdrawal Cycles:

- The connectors typically support 1000 to 5000 mating cycles, ensuring long-term reliability and stability even after repeated use.

- Connector Types:

- Common connector types include quick-connect connectors, threaded connectors, and locking connectors, allowing for flexible options based on specific connection needs.

- Materials:

- The housings are usually made of aluminum alloy or stainless steel, while the contacts are typically composed of copper alloy or silver-plated materials, providing excellent conductivity and corrosion resistance.

- Size and Weight:

- Heavy-duty aviation connectors are generally larger in size to accommodate higher current and stronger mechanical performance, resulting in a relatively heavier weight to ensure stable connections.

Conclusion

In conclusion, heavy-duty aviation connectors offer outstanding durability and reliability, providing stable electrical connections even in extreme environments. With features like waterproofing, dustproofing, shock resistance, and high temperature tolerance, these connectors are widely used across industries such as aerospace, military, railways, and industrial equipment. Their strong electrical performance, variety of connector styles, and high protection ratings make them the ideal choice for applications requiring high-strength electrical connections.