Gear coupling

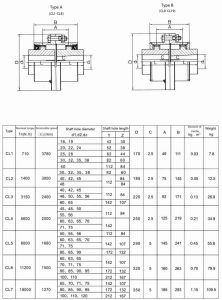

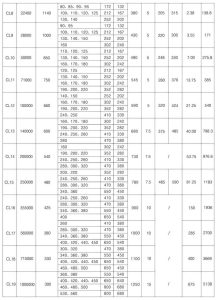

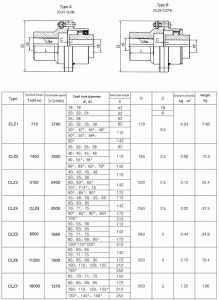

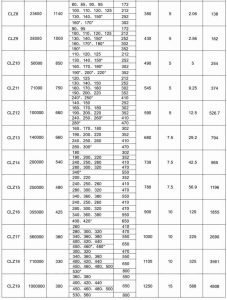

Gear Couplings Parameters:

- Maximum Allowable Torque: 710 Nm to 1,000,000 Nm

- Maximum Speed: 7100 rpm to 700 rpm

- Coupling Material: ZG430-640, 45 steel

- Coupling Types: Full-tooth couplings and half-tooth couplings

- Custom Options: You can provide your own drawings, and we will manufacture according to the specified dimensions.