European Single girder crane end carriage

Specifications of European Single girder crane end carriage

- Models: EC11, EC14, EC16, EC20, EC25

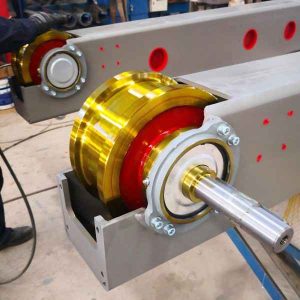

- Wheel Material: QT700 , 40Cr

- Wheel Connection Types:

- Internal splines

- Cylindrical shafts

- Wheel Groove Width: Determined based on the rail model

- Custom Design: Non-standard customization available. You can provide drawings, and we will manufacture according to the specified dimensions.

The European Single Girder Crane End Carriage is a key component widely used in modern crane systems. It typically supports the main beam of the crane and facilitates horizontal movement along tracks. Compared to traditional end carriages, the European single girder crane end carriage offers higher performance, a more compact structure, and a lighter weight. Designed according to European standards, it is suitable for various industrial applications, especially in environments where high precision, low noise, and low vibration are required.

European Single Girder Crane End Carriage Main Features:

- Structural Design: The European single girder crane end carriage adopts a steel frame structure, which provides both high strength and relatively low weight. Its design is typically more compact, helping to save space and improve efficiency. The end carriage is equipped with an electric drive system, wheel sets, and tracks to facilitate the crane’s horizontal movement.

- Drive System: The end carriage is equipped with a highly efficient electric drive system, often using an AC motor. This allows the end carriage to provide stable travel speeds and high load capacity. Moreover, the drive system not only minimizes energy consumption but also ensures smooth operation over extended periods.

- Track and Wheel Sets: The track system is designed to standardized specifications, ensuring proper alignment with both the main beam and the crane tracks. The wheel sets are typically made from high-strength materials, offering good wear resistance and the ability to bear heavy loads.

- Efficiency and Precision: The design of the European single girder crane end carriage focuses on high efficiency and precision, allowing the system to operate with low noise and low vibration. This ensures smooth crane operation, making it especially suitable for environments with stringent noise and vibration requirements.

Applications:

- Industrial Lifting Equipment: The European single girder crane end carriage is widely used in production lines, warehouses, and ports, particularly in applications that demand precise control and high load capacity, such as the steel, mechanical processing, power, and chemical industries.

- Automated Storage Systems: In automated storage systems, the end carriage can perform precise lifting and retrieval tasks, improving warehouse efficiency.

- Equipment Maintenance: It is also suitable for locations where frequent lifting and maintenance of equipment are necessary, such as repair workshops and installation zones.

Advantages:

- Compact Structure: Its compact design helps save space and reduces the installation footprint.

- High Performance: Compared to traditional end carriages, the European single girder crane end carriage offers higher load capacity, greater stability, and a longer service life.

- Energy Efficiency: The electric drive system has lower energy consumption, which helps reduce operational costs.

- Low Noise and Vibration: Due to advanced design and manufacturing techniques, the end carriage operates with minimal noise and vibration, ensuring a stable working environment.

- High Safety: It incorporates high-standard safety features, including overload protection and emergency stop systems, ensuring operator safety.

Conclusion:

The European single girder crane end carriage is a high-performance crane component that is compact, efficient, and offers low noise and vibration. It is ideal for a variety of industrial applications, particularly where precise control and high performance are needed. Its advanced design helps improve operational efficiency and reduce energy consumption. However, its higher initial investment cost and ongoing maintenance requirements should also be considered.

European Single girder crane end carriage Selection table |

|||||||||||

| Lifting capacity (t) |

Crane span (m) |

End carriages type | suggestion Rail type |

FFT Series Gear Motors |

F Series Gear Motors |

Lifting capacity (t) |

Crane span (m) |

End carriages type | suggestion Rail type |

FFT Series Gear Motors |

F Series Gear Motors |

| 3.2 | 7.5 | EC14-17 | P22 | FFT3-0.3KW | FA37-0.37KW | 5 | 7.5 | EC14-17 | P22 | FFT3-0.3KW | FA37-0.37KW |

| 10.5 | EC14-17 | P22 | FFT3-0.3KW | FA37-0.37KW | 10.5 | EC14-17 | P22 | FFT3-0.3KW | FA37-0.37KW | ||

| 13.5 | EC14-17 | P22 | FFT3-0.3KW | FA37-0.37KW | 13.5 | EC14-17 | P22 | FFT3-0.3KW | FA37-0.37KW | ||

| 16.5 | EC14-22 | P22 | FFT3-0.3KW | FA37-0.37KW | 16.5 | EC16-22 | P22 | FFT3-0.65KW | FA37-0.55KW | ||

| 19.5 | EC16-27 | P22 | FFT3-0.65KW | FA37-0.55KW | 19.5 | EC16-27 | P22 | FFT3-0.65KW | FA37-0.55KW | ||

| 22.5 | EC16-31 | P22 | FFT3-0.65KW | FA37-0.55KW | 22.5 | EC20-31 | P22 | FFT4-0.65KW | FA37-0.75KW | ||

| 25.5 | EC16-37 | P22 | FFT3-0.65KW | FA37-0.55KW | 25.5 | EC20-37 | P22 | FFT4-0.65KW | FA37-0.75KW | ||

| 28.5 | EC20-37 | P22 | FFT4-0.65KW | FA37-0.75KW | 28.5 | EC20-37 | P22 | FFT4-0.65KW | FA37-0.75KW | ||

| 31.5 | EC20-40 | P22 | FFT4-0.65KW | FA37-0.75KW | 31.5 | EC20-40 | P22 | FFT4-0.65KW | FA37-0.75KW | ||

| 8 | 7.5 | EC20-17 | P22 | FFT4-0.65KW | FA37-0.75KW | 10 | 7.5 | EC20-17 | P22 | FFT4-0.65KW | FA37-0.75KW |

| 10.5 | EC20-22 | P22 | FFT4-0.65KW | FA37-0.75KW | 10.5 | EC20-22 | P22 | FFT4-0.65KW | FA37-0.75KW | ||

| 13.5 | EC20-22 | P22 | FFT4-0.65KW | FA37-0.75KW | 13.5 | EC20-22 | P22 | FFT4-0.65KW | FA37-0.75KW | ||

| 16.5 | EC20-27 | P22 | FFT4-0.65KW | FA37-0.75KW | 16.5 | EC20-27 | P22 | FFT4-0.65KW | FA37-0.75KW | ||

| 19.5 | EC20-27 | P22 | FFT4-0.65KW | FA37-0.75KW | 19.5 | EC25-27 | P22 | FFT4-1.1KW | FA47-1.1KW | ||

| 22.5 | EC20-31 | P22 | FFT4-0.65KW | FA37-0.75KW | 22.5 | EC25-31 | P22 | FFT4-1.1KW | FA47-1.1KW | ||

| 25.5 | EC25-36 | P22 | FFT4-1.1KW | FA47-1.1KW | 25.5 | EC25-36 | P22 | FFT4-1.1KW | FA47-1.1KW | ||

| 28.5 | EC25-36 | P30 | FFT4-1.1KW | FA47-1.1KW | 28.5 | EC25-36 | P30 | FFT4-1.1KW | FA47-1.1KW | ||

| 31.5 | EC25-40 | P30 | FFT4-1.1KW | FA47-1.1KW | 31.5 | EC25-40 | P30 | FFT4-1.1KW | FA47-1.1KW | ||

|

1.Travelling machinery frequency conversion speed regulation:0-32m/min; |

|||||||||||