European crane hook

European crane hook parameters:

- Specifications: 3.2t, 5t, 10t, 16t, 20t, 32t, 50t, 75t, 100t, 125t, 160t, 200t, 320t, 400t, 500t

- Working level: M5, M6, M7,

- Hook material: 35CrMo (≤100t), 34Cr2Ni2Mo (>100t)

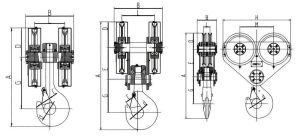

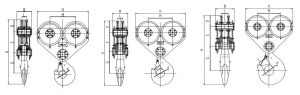

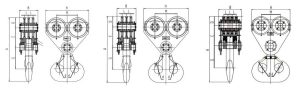

- Hook pulley assembly form: straight pulley, inclined pulley

- Hook type: forged single hook, forged double hook

The European crane hook is a specialized lifting component commonly used in overhead cranes, gantry cranes, and other lifting systems in industrial settings. Known for its high safety standards, durability, and efficient design, the European crane hook is particularly suited to the demanding operational requirements found in European industries. It plays a key role in securely connecting the crane’s hoisting system (e.g., wire rope or chain) to the load, ensuring that materials are lifted, moved, and positioned safely and efficiently.

Key Features of European Crane Hook

- High Load Capacity:

European crane hooks are designed to handle a wide range of load capacities, from lighter industrial loads to extremely heavy lifting requirements. The load capacity is typically defined by the crane’s overall specifications, with hooks engineered to match those requirements and safely support the lifted loads. - Material and Construction:

The hooks are made from high-quality, high-strength steel or alloy materials that provide excellent durability, resistance to wear, and strength under extreme stress. Many European crane hooks are manufactured using advanced forging or casting methods to ensure uniformity and strength in the hook’s structure. - Safety Features:

European crane hooks are equipped with advanced safety mechanisms to ensure secure lifting. This often includes features like:- Safety Latches or Locks: To prevent the load from accidentally detaching during lifting.

- Swivel Function: Some European crane hooks feature a swivel mechanism, allowing the hook to rotate freely, reducing the risk of rope twisting and ensuring smoother load handling.

- Grooved or Tapered Tips: To ensure a secure attachment between the hook and the load, preventing slippage during operation.

- Design Variety:

European crane hooks come in various designs to suit different lifting requirements:- Single Hooks: For standard lifting applications.

- Double Hooks: Used for higher capacity or for lifting loads that require a more balanced lift.

- Specialized Hooks: For handling unique types of loads, such as coils, plates, or irregular shapes. Some European hooks are designed with magnetic capabilities or custom grips for specific applications.

- Corrosion Resistance:

Many European crane hooks are designed to operate in challenging environments, such as high-humidity areas, extreme temperatures, or corrosive environments. They are often coated with protective layers, such as galvanization or specialized paints, to enhance their resistance to corrosion and prolong their service life.

The European crane hook is a key component in ensuring the safe and efficient lifting of heavy loads in industrial settings. With its robust construction, safety features, and compliance with European standards, the European crane hook is well-suited for use in diverse applications, from manufacturing plants to shipping ports. It combines high performance with durability, making it an indispensable part of modern lifting systems.

5t 10t 16t

20t 32t 50t

75t 100t 160t

| Drawing No. | Lifting capacity | Size(mm) | |||||||||

| A | B | E | G | D | L | H | M | C | d | ||

| XG005 | 5t | 650 | 327 | / | 340 | 193 | 202 | / | / | 63 | 80 |

| XG010 | 10t | 1000 | 458 | 295 | 300 | 243 | 310 | / | / | 90 | 112 |

| XG016 | 16t | 1200 | 279 | 390 | 380 | 200 | 87 | 960 | 480 | / | 140 |

| XG020 | 20t | 1290 | 300 | 400 | 430 | 200 | 100 | 960 | 480 | / | 160 |

| XG032 | 32t | 1560 | 365 | 460 | 520 | 250 | 120 | 1198 | 590 | 160 | 200 |

| XG050 | 50t | 1760 | 470 | 500 | 620 | 250 | 180 | 1198 | 590 | 200 | 250 |

| XG075 | 75t | 1783 | 518 | 550 | 600 | 285 | 120 | 1206 | 600 | / | 224 |

| XG125 | 125t | 1935 | 565 | 580 | 678 | 285 | 135 | 1200 | 600 | / | 250 |

| XG160 | 160t | 2050 | 722 | 630 | 691.5 | 285 | 130 | 1200 | 600 | / | 280 |