Electric Chain Hoist

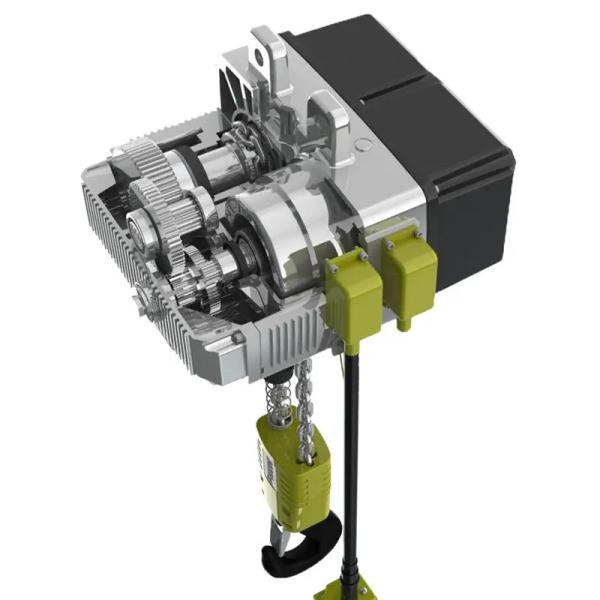

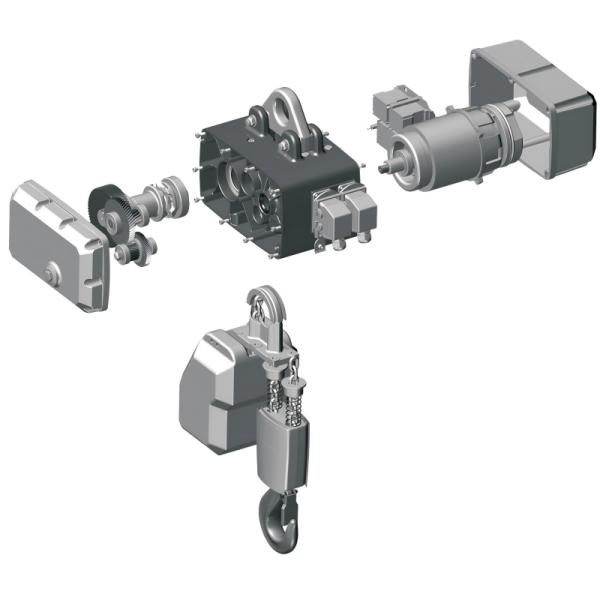

Electric Chain Hoist Main Features

- Compact and lightweight for easy operation.

- Can be installed on suspended I-beams, curved tracks, jib crane guide rails, or fixed lifting points for handling heavy loads.

- Utilizes chain drive for high efficiency and simple maintenance.

- Equipped with an independent gearbox system and a long-lasting oil-bath lubrication system.

- Features disc-type DC electromagnetic braking for large braking torque, smooth operation, fast response, and low noise.

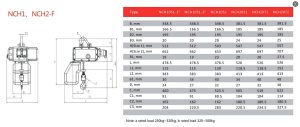

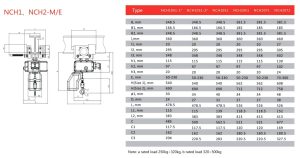

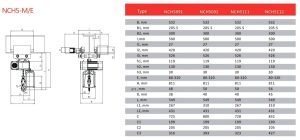

NCH Chain Hoist Selection Table

| Lifting capacity (kg) |

FEM | ISO | Type | Power (KW) |

Hoisting speed (M/min) |

Number of chains |

| 250 | 3m | M6 | NCH105102508 | 0.75/0.18 | 8/2 | 1 |

| 250 | 2m | M5 | NCH105102516 | 0.75/0.18 | 16/4 | 1 |

| 320 | 2m | M5 | NCH105103208 | 0.75/0.18 | 8/2 | 1 |

| 320 | 1Am | M4 | NCH105103216 | 0.75/0.18 | 16/4 | 1 |

| 500 | 1Am | M4 | NCH105105008 | 0.75/0.18 | 8/2 | 1 |

| 500 | 3m | M6 | NCH207105008 | 1.9/0.45 | 8/2 | 1 |

| 500 | 2m | M5 | NCH205105016 | 1.9/0.45 | 16/4 | 1 |

| 630 | 1Am | M4 | NCH105206308 | 0.75/0.18 | 8/2 | 2 |

| 630 | 2m | M5 | NCH207106308 | 1.9/0.45 | 8/2 | 1 |

| 630 | 1Am | M4 | NCH205106316 | 1.9/0.45 | 16/4 | 1 |

| 1000 | 1Am | M4 | NCH105210004 | 0.75/0.18 | 4/1 | 2 |

| 1000 | 1Am | M4 | NCH207110008 | 1.9/0.45 | 8/2 | 1 |

| 1000 | 2m | M5 | NCH509110016 | 3.5/0.88 | 16/4 | 1 |

| 1600 | 2m | M5 | NCH207216004 | 1.9/0.45 | 4/1 | 2 |

| 1600 | 2m | M5 | NCH509116008 | 3.5/0.88 | 8/2 | 1 |

| 2000 | 1Am | M4 | NCH207220004 | 1.9/0.45 | 4/1 | 2 |

| 2000 | 2m | M5 | NCH511120006 | 3.5/0.88 | 6.3/1.6 | 1 |

| 2000 | 1Am | M4 | NCH511120008 | 3.5/0.88 | 8/2 | 1 |

| 2500 | 2m | M5 | NCH509225004 | 3.5/0.88 | 4/1 | 2 |

| 2500 | 1Am | M4 | NCH511125006 | 3.5/0.88 | 6.3/1.6 | 1 |

| 3200 | 2m | M5 | NCH511232003 | 3.5/0.88 | 3.2/0.75 | 2 |

| 3200 | 1Am | M4 | NCH509232004 | 3.5/0.88 | 4/1 | 2 |

| 4000 | 1Am | M4 | NCH511240004 | 3.5/0.88 | 3.2/0.75 | 2 |

| 4000 | 2m | M5 | NCH511240003 | 3.5/0.88 | 4/1 | 2 |

| 5000 | 1Am | M4 | NCH511250003 | 3.5/0.88 | 3.2/0.75 | 2 |

| 7500 | 1Am | M4 | NCH511375002 | 3.5/0.88 | 2.1/0.5 | 3 |