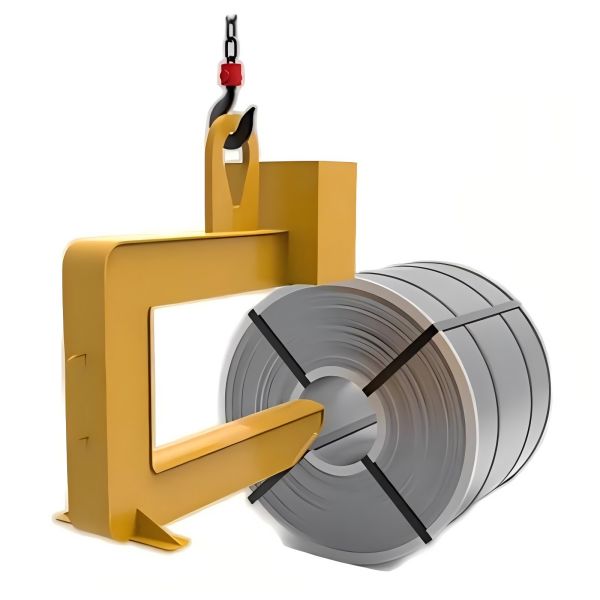

C-type hook

Coil C-Type Hook,coil hook,Overhead Crane Steel Coil C-Type Hook,Crane C-hook,C-type spreader,C-type hook,Crane C-type spreader,Special Crane Spreader

Introduction to C-Type Hook

The C-type hook is a widely used lifting device in cranes and hoisting equipment, named after its “C” shape. It is primarily used for carrying and lifting heavy loads and is commonly employed in material handling and lifting operations across industrial production, warehouse logistics, and construction sites. Due to its simple structure and strong load-bearing capacity, the C-type hooks is a common tool in various lifting tasks.

C-Type Hook Key Features

- Simple Structure: The C-type hooks features a straightforward design with a C-shaped appearance, making it both easy to manufacture and use. It is typically made of high-strength steel or alloy material, which provides excellent load-bearing capacity and durability.

- Strong Load-Bearing Capacity: The design of the C-type hooks enables it to withstand significant tension and weight, making it suitable for lifting heavy objects. Through a well-designed structure, the C-type hook offers efficient and safe support during lifting operations.

- Strong Adaptability: The C-type hook is widely used on cranes, tower cranes, hoist trucks, and other equipment, capable of handling various sizes and shapes of materials. It is used not only for lifting large components but also for moving industrial materials like steel, machinery, and construction materials.

- High Safety: Many C-type hooks are equipped with anti-fall features such as safety locks or specialized hook mouth designs. These mechanisms effectively prevent items from falling during lifting, ensuring that lifting operations remain safe.

Working Principle

The working principle of a C-type hooks is simple. It typically connects to the lifting equipment’s wire rope or chain. When lifting, the wire rope secures the load through the hook’s opening. The crane’s lifting power is then used to hoist the load. Because of the hook’s design, the hook mouth provides strong support to hold the load firmly, maintaining stability throughout the lifting process.

Advantages

- Efficiency and Reliability: The C-type hooks design allows it to lift heavy items quickly and reliably, making it suitable for frequent lifting operations.

- Cost-Effective: Due to its simple structure and strong materials, the production cost of a C-type hook is relatively low, and maintenance costs are minimal, making it an economical and practical lifting tool.

- Ease of Operation: The C-type hook is easy to operate, with fast connection and disconnection, reducing preparation time and improving work efficiency.

- High Safety: C-type hooks equipped with safety locks and anti-fall features effectively reduce the risk of items falling during the lifting process, ensuring safety during operations.

Conclusion

In conclusion, the C-type hooks, with its simple yet robust design, is an essential lifting tool widely used across various lifting tasks. Its structure enables it to carry heavy loads, adapt to diverse lifting needs, and ensure high safety and ease of operation. Whether at construction sites, industrial plants, ports, or warehouses, the C-type hooks plays a crucial role in improving work efficiency and ensuring safety during lifting operations.