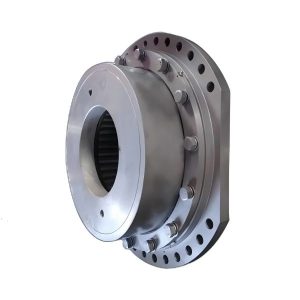

Angle box type crane wheel

Angle box type crane wheel Parameters:

- Specifications: Φ250, Φ350, Φ400, Φ500, Φ600, Φ700, Φ800

- Wheel Material: ZG430-640, 45 steel, 50SiMn, 65Mn, 42CrMo

- Wheel Type: Double flange, Single flange, No flange

- Wheel Groove Width: Determined according to track model

- Custom Orders: We can manufacture based on your drawings and dimensions provided.

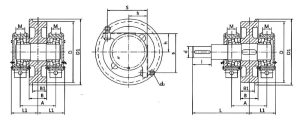

Single-Rim Wheelset

| Wheel diameter | Drawing No. | Size (mm) | ||||||||||||

| D | D1 | B | B1 | A | L | L1 | h | S | M | d | I | d1 | ||

| Φ250 | L754 | 250 | 280 | 90 | 70 | 180 | 237 | 130 | 80 | 180 | 30 | 45 | 82 | M20 |

| L755 | 250 | 280 | 90 | 70 | 180 | / | 130 | 80 | 180 | 30 | / | / | ||

| φ315 | L774 | 315 | 345 | 100 | 81 | 200 | 320 | 150 | 105 | 225 | 50 | 65 | 105 | |

| L775 | 315 | 345 | 100 | 81 | 200 | / | 150 | 105 | 225 | 50 | / | / | ||

| Φ350 | L756 | 350 | 380 | 100 | 81 | 200 | 320 | 150 | 105 | 225 | 50 | 65 | 105 | |

| L757 | 350 | 380 | 100 | 81 | 200 | / | 150 | 150 | 225 | 50 | / | / | ||

| φ400 | L758 | 400 | 440 | 120 | 100 | 240 | 365 | 170 | 120 | 260 | 50 | 80 | 130 | |

| L759 | 400 | 440 | 120 | 100 | 240 | / | 170 | 120 | 260 | 50 | / | / | ||

| Φ500 | L762 | 500 | 540 | 130 | 110 | 270 | 365 | 195 | 140 | 300 | 50 | 80 | 130 | |

| L763 | 500 | 540 | 130 | 110 | 270 | / | 195 | 140 | 300 | 50 | / | / | ||

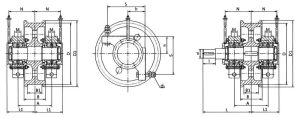

Double-Rim Wheelset

| Wheel diameter | Drawing No. | Size (mm) | ||||||||||||

| D | D1 | A | B | B1 | L | L1 | h | S | M | d | I | d1 | ||

| φ500 | L764 | 500 | 540 | 280 | 210/160 | 150/100 | 400 | 230 | 140 | 310 | 50 | 75 | 105 | M24 |

| L765 | 500 | 540 | 280 | / | 230 | 140 | 310 | 50 | / | / | ||||

| Φ600 | L766 | 600 | 640 | 280 | 210/160 | 150/100 | 415 | 230 | 140 | 310 | 50 | 85 | 130 | |

| L767 | 600 | 640 | 280 | / | 230 | 140 | 310 | 50 | / | / | ||||

| φ700 | L768 | 700 | 750 | 315 | 210/160 | 150/100 | 455 | 260 | 160 | 350 | 80 | 90 | 130 | M30 |

| L769 | 700 | 750 | 315 | / | 260 | 160 | 350 | 80 | / | / | ||||

| φ700 | L770 | 800 | 850 | 365 | 210/160 | 150/100 | 500 | 300 | 190 | 410 | 90 | 95 | 130 | |

| L771 | 800 | 850 | 365 | / | 300 | 190 | 410 | 90 | / | / | ||||

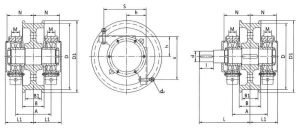

Heavy-Duty Wheelset

| Wheel diameter | Drawing No. | Size (mm) | ||||||||||||

| D | D1 | B | B1 | A | L | L1 | h | S | M | d | I | d1 | ||

| Φ600 | L174B | 600 | 650 | 210/160 | 150/100 | 325

325 |

470 | 255 | 180 | 390 | 70 | 95 | 130 | M24 |

| L175B | 600 | 650 | / | 255 | 180 | 390 | 70 | / | / | |||||

| φ700 | L176B | 700 | 750 | 210/160 | 150/100 | 360

360 |

500 | 280 | 200 | 440 | 80 | 110 | 165 | M30 |

| L177B | 700 | 750 | / | 280 | 200 | 440 | 80 | / | / | |||||

| Φ700 | L178B | 700 | 750 | 210/160 | 150/100 | 380

380 |

500 | 305 | 220 | 485 | 80 | 110 | 165 | |

| L179B | 700 | 750 | / | 305 | 220 | 485 | 80 | / | / | |||||

| φ800 | L196B | 800 | 850 | 210/160 | 150/100 | 380

380 |

500 | 305 | 220 | 485 | 80 | 110 | 165 | |

| L197B | 800 | 850 | / | 305 | 220 | 485 | 80 | / | / | |||||