C-Type Hook Introduction

C-type hook play an indispensable role in modern industrial lifting operations due to their unique structural design. Specifically engineered for specialized working conditions, these hooks are widely used in industries such as steel manufacturing, shipbuilding, and logistics.

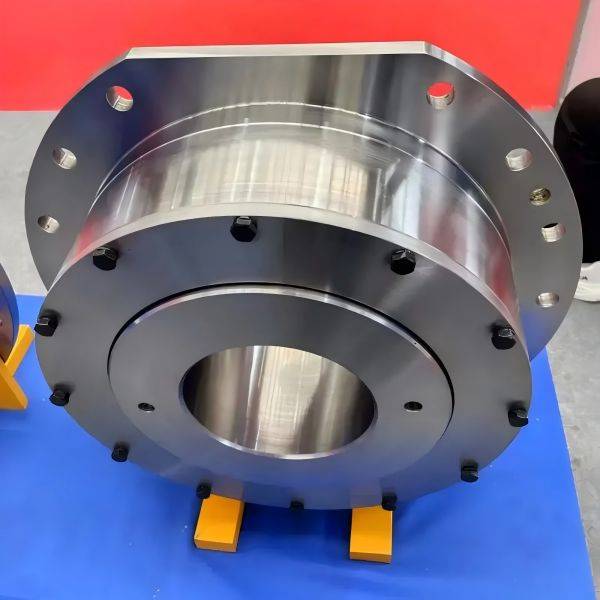

Structural Features of C-Type Hooks

Manufactured from high-strength alloy steel, C-type hooks feature a distinctive “C”-shaped curvature. Their key design elements include:

- An open end for easy material loading and unloading

- A closed end that bears the primary load

- An inner surface often lined with anti-slip grooves or padding

- Variations such as single or double hooks based on load requirements

Thanks to this structure, C-type hooks are particularly suitable for lifting coiled and cylindrical materials.

Primary Applications

In the steel industry, C-type hooks are extensively used for handling steel coils. Their curved inner surface perfectly matches the coil’s outer diameter, ensuring a secure grip while preventing surface damage. Additionally:

- In the paper industry, they transport large paper rolls.

- In shipbuilding, they lift pipes and cylindrical components.

- In logistics and warehousing, they handle cable reels, tires, and other ring-shaped items.

Technical Advantages

Compared to traditional lifting tools, C-type hook offer several benefits:

- Even Load Distribution – The wraparound design reduces localized stress.

- Efficient Operation – Quick attachment and detachment improve productivity.

- Enhanced Safety – The secure grip minimizes the risk of material slippage.

- Customizability – They can be tailored in size and material for different applications.

Key Usage Considerations

To ensure safe operation, the following precautions must be taken:

- Inspect before use – Check for cracks or deformations.

- Avoid overloading – Never exceed the rated capacity.

- Ensure proper fit – The material must fully contact the hook surface.

- Perform regular maintenance – Conduct non-destructive testing periodically.

- Train operators – Only qualified personnel should handle C-type hooks.

Moreover, implementing a strict inspection and logging system is essential for long-term safety.

Conclusion

As industrial technology advances, C-type hooks continue to evolve in both design and material science. Smart variants with integrated weighing and anti-sway features are now emerging. As a critical crane attachment, C-type hooks provide reliable and efficient lifting solutions, ensuring their growing relevance in modern industrial applications.