The Role of Crane Drums in Cranes

1. What Are Crane Drums?

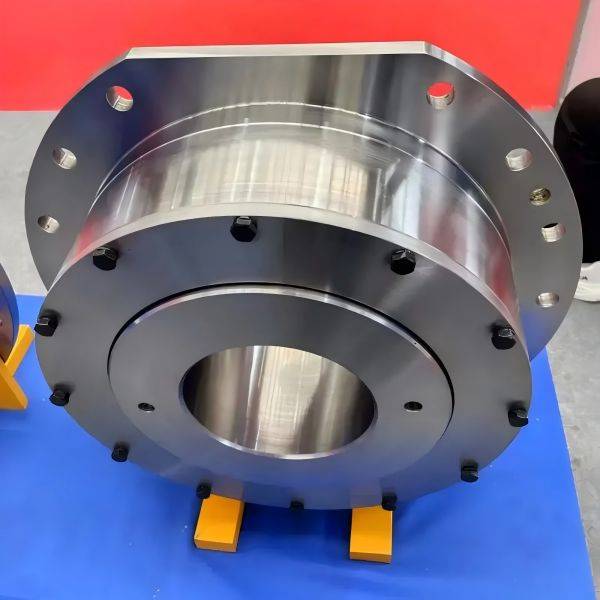

Crane drums play a crucial role in a crane’s lifting mechanism by winding and unwinding the wire rope, enabling the hook or other lifting devices to move up and down. The quality and design of the drum directly impact the crane’s efficiency, safety, and lifespan. Typically, manufacturers construct crane drums from high-strength steel and equip them with spiral grooves, end plates, bearing seats, and drive mechanisms. These features ensure that the wire rope remains properly aligned and evenly tensioned, preventing tangling or misalignment.

2. The Core Functions of Crane Drum in Cranes

(1) Winding the Wire Rope to Control Hook Movement

First and foremost, crane drums allow the hook or lifting attachment to rise and descend by winding and releasing the wire rope. When the motor drives the drum’s rotation, the rope tightens or loosens accordingly, completing the lifting or lowering process. Well-designed drums ensure that the rope aligns properly, reducing friction and preventing excessive wear.

(2) Providing Load Support for Safe Operations

Additionally, crane drums bear the tension of the wire rope and the weight of the lifted load. Because of this, engineers design them with high strength and rigidity to prevent deformation or failure under heavy loads. Furthermore, the drum’s diameter, thickness, and material selection play a critical role in maintaining stability during long-term and high-intensity operations.

(3) Reducing Wire Rope Wear and Extending Service Life

To further enhance durability, high-quality crane drums feature spiral grooves that guide the wire rope along a fixed path. By minimizing rope friction, these grooves significantly reduce wear and tear, thereby extending the rope’s service life. This design proves especially beneficial in heavy-duty and high-frequency applications, as it lowers maintenance costs and improves operational efficiency.

(4) Enhancing Safety by Integrating with the Braking System

Moreover, crane drum work in conjunction with braking systems to ensure safe lifting operations. While the hook moves up and down, the braking system provides the necessary stopping force, preventing sudden drops or uncontrolled movements. When the motor stops, the brakes lock the drum in place, keeping the hook securely positioned and preventing accidents.

(5) Optimizing Crane Structure for Smooth Performance

In addition, well-designed crane drum contribute to an optimized crane structure, making it more compact and efficient. By incorporating precision engineering and balance testing, manufacturers ensure that crane drums operate smoothly, reducing vibrations and noise. As a result, operators experience greater precision and comfort while handling loads.

3. Conclusion

In conclusion, crane drums serve as a vital component in cranes, controlling the hook’s movement while ensuring safety, efficiency, and longevity. High-quality crane drums align the wire rope properly, reduce wear, and provide stable load-bearing capacity. Additionally, when integrated with braking systems, they further enhance operational safety. As industrial technology advances, engineers continue to refine drum designs to create more efficient and reliable lifting solutions, supporting the growth of modern infrastructure and industrial development.