Selection Standards and Characteristics of European Crane End Carriages

The European crane end carriage is a vital component of the overhead crane system, designed to support the crane bridge and enable it to move smoothly along the tracks. Correctly selecting the end carriage ensures the crane system operates efficiently, improves safety, and enhances overall performance. Below are the selection standards and characteristics of European crane end carriages.

1. European Crane End Carriages Rated Load

- Selection Standard: The rated load of the end carriage must match the total load it is required to support, including the weight of the crane bridge, hoist, and the maximum lifting capacity. These loads must be considered during the selection process to ensure the end carriage can safely withstand the forces and stresses during operation.

- Characteristics: By selecting the correct rated load, the end carriage can prevent overloading, minimize the risk of structural damage, and ensure the crane operates within its safety limits. Overloading can lead to failure of the end carriage and other crane components.

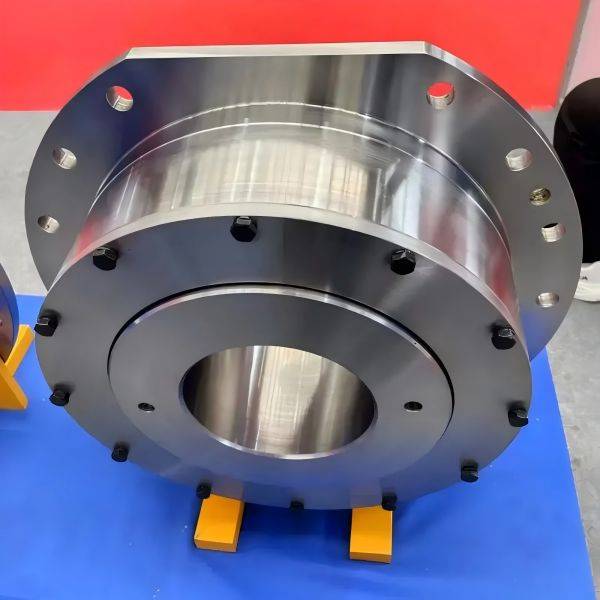

2. Wheel Size and Material

- Selection Standard: The wheel diameter and material should be selected based on the type of track, load requirements, and the crane’s operating environment. Typically, larger wheels are chosen for heavier loads and for tracks with larger tolerances.

- Characteristics: Larger wheels distribute the load more evenly and reduce wear, while stronger materials (e.g., forged steel) ensure that the wheels can withstand higher pressures, extending their service life and reducing maintenance needs.

3. Speed and Operating Conditions

- Selection Standard: The end carriage must be able to support the crane’s required speed and handle different types of operations (e.g., frequent starts and stops, continuous operation, or intermittent use). This includes factors such as acceleration, deceleration, and the frequency of crane use.

- Characteristics: For high-speed applications, the end carriage should be designed with high-speed bearings and lubrication systems that meet faster operational demands. For applications with continuous operation, the end carriage should be capable of handling heat dissipation and reducing wear.

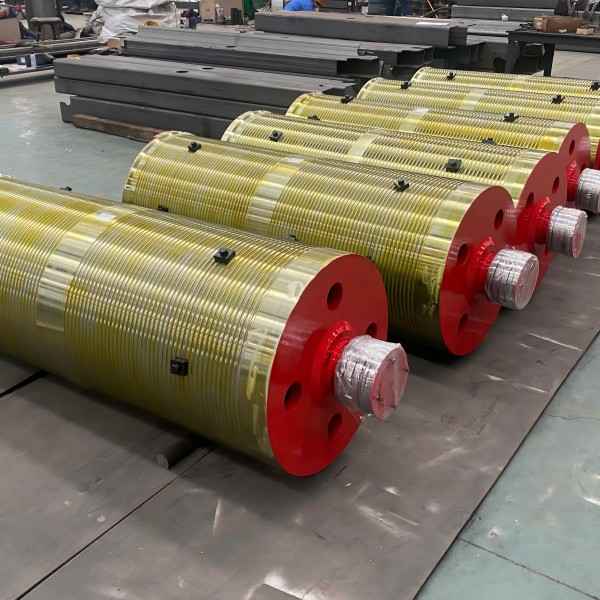

4. Structural Design and Rigidity

- Selection Standard: The structural design of the end carriage must provide sufficient rigidity and strength to support the crane bridge. It should be made of high-quality steel, and the thickness should be designed to withstand bending, twisting, and other stresses.

- Characteristics: A rigid end carriage ensures stable crane movement, reduces vibrations, and maintains precision and reliability. A strong end carriage can endure varying operational loads and prolong the service life of the system.

5. Precision and Accuracy

- Selection Standard: European crane end carriages are often used in applications that require high precision, such as in manufacturing or assembly lines. The end carriage should allow precise travel along the tracks, ensuring smooth movement without swaying or misalignment.

- Characteristics: Accurate wheel alignment, precision bearings, and efficient lubrication systems are essential for maintaining the crane’s operational precision. This helps reduce wear on the wheels and tracks, increasing the overall lifespan of the equipment.

6. European Crane End Carriages Safety Features

- Selection Standard: Safety is a crucial factor in the design of the end carriage. It should be equipped with safety features such as anti-collision devices, overload protection, and emergency stop systems.

- Characteristics: Safety features help prevent accidents, minimize damage in case of failures, and ensure the crane operates safely under all conditions. For example, overload protection automatically stops the crane if the load exceeds the safe limit, preventing damage to the equipment.

7. Environmental Considerations

- Selection Standard: The end carriage should be selected based on the environmental conditions in which it will operate, including factors such as temperature, humidity, exposure to corrosive substances, and the presence of dust or debris that could affect its performance.

- Characteristics: For cranes operating in harsh environments (e.g., marine, chemical plants, or outdoor operations), corrosion-resistant materials (e.g., stainless steel, coated steel) and sealed bearings are essential to prolong the end carriage’s service life and ensure smooth operation.

8. Maintenance and Accessibility

- Selection Standard: The end carriage should be designed to allow easy access for maintenance, inspection, and lubrication. It should also include features that enable performance monitoring and early fault detection.

- Characteristics: Regular maintenance and lubrication ensure that the end carriage operates efficiently and safely. A design that allows easy access reduces downtime and maintenance costs, making the crane system more cost-effective over its lifetime.

9. Compatibility with Other Crane Components

- Selection Standard: The end carriage must be compatible with other components of the crane system, including the crane bridge, hoist, and electrical system. Its design should ensure seamless integration with the overall crane system.

- Characteristics: Ensuring compatibility improves the overall system’s performance and reduces mechanical and electrical issues. Proper alignment with the crane bridge and hoist system guarantees smooth operation and reduces wear on components.

10. Compliance with Standards

- Selection Standard: The end carriage must comply with relevant European and international standards, such as EN 15011 (for overhead traveling cranes) and ISO 4301 (for crane classification). These standards define the necessary safety, design, and performance requirements for the carriage.

- Characteristics: End carriages that meet these standards have undergone rigorous testing and certification, ensuring that they meet industry requirements for strength, durability, and performance, thus guaranteeing the safety and reliability of the crane system.

European Crane End Carriages Summary:

In conclusion, selecting a European crane end carriage involves evaluating several factors, including rated load, wheel size, speed, structural design, precision, safety features, and environmental conditions. By carefully considering these factors, users can ensure optimal performance, safety, and longevity of the crane system. Proper selection minimizes the risk of failure, reduces maintenance costs, and extends the service life of both the end carriage and the entire crane system, ultimately improving operational efficiency.