The selection standards and characteristics of an overhead crane drum are critical for ensuring the reliable operation of the crane system. The drum is primarily responsible for winding and unwinding the wire rope, which is essential for lifting loads. Therefore, its design and selection must meet the crane’s load requirements, environmental conditions, and safety standards. Below is a detailed analysis of the selection criteria and features:

1. overhead crane drum Rated Load

- Selection Standard: The rated load of the drum should match the rated lifting capacity of the crane and the maximum tensile strength of the wire rope. The drum must be designed to withstand the force exerted by the wire rope under maximum load conditions.

- Characteristics: A drum with an insufficient rated load may suffer from excessive stress during operation, leading to deformation or failure. Therefore, it is essential to choose a drum whose load capacity aligns with the crane’s operational needs.

2. overhead crane drum Wire Rope Capacity

- Selection Standard: The drum’s capacity must accommodate the length and diameter of the selected wire rope, ensuring that the rope can be smoothly wound and unwound without causing tangling or excessive bending.

- Characteristics: Proper wire rope capacity ensures that the rope wears evenly, extending its service life and preventing operational issues such as excessive friction or jamming during winding and unwinding.

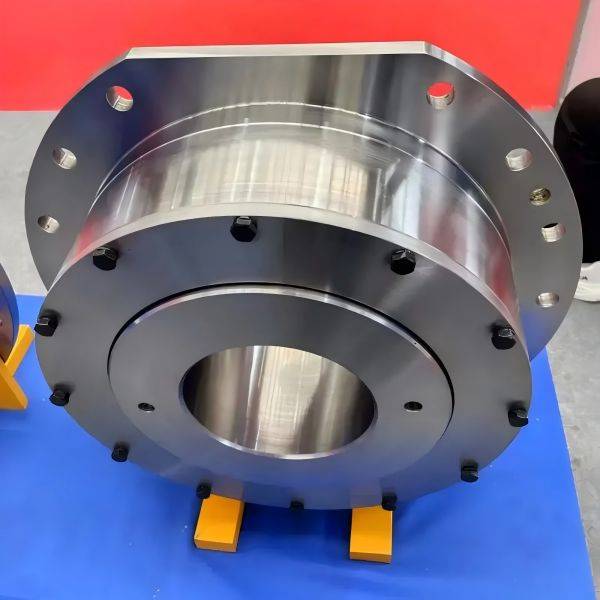

3. Material

- Selection Standard: The drum should be made from materials with high strength, wear resistance, and corrosion resistance. Common materials include carbon steel, alloy steel, and stainless steel. The material choice should depend on the operating environment (e.g., high temperature, humidity, corrosion).

- Characteristics: Alloy steel and stainless steel offer better wear and corrosion resistance, making them suitable for harsh environments. Carbon steel, on the other hand, is widely used in standard conditions and is more cost-effective.

4. overhead crane Drum Diameter

- Selection Standard: The diameter of the drum should be selected based on the diameter of the wire rope. Typically, the drum diameter should be several times greater than the diameter of the rope to prevent excessive bending and fatigue.

- Characteristics: A suitable drum diameter helps minimize the wear on the wire rope and reduces fatigue, ensuring that the rope is wound and unwound evenly, without causing premature damage.

5. Design of the Drum

- Selection Standard: The drum should be designed to ensure smooth winding and unwinding of the wire rope without tangling. There are single-slot and multi-slot designs; the choice depends on the number and type of wire ropes used. The inner and outer surfaces of the drum must be smooth, free of burrs, and have a regular shape.

- Characteristics: A multi-slot design helps distribute the wire rope evenly, reducing friction. The smoothness of the drum’s surface is critical as it directly affects the wire rope’s service life, preventing sharp edges or imperfections from causing damage.

6. Bearings and Drive System

- Selection Standard: The drum should be equipped with appropriate bearings to ensure smooth operation during use. The bearing system must have a high load capacity and wear resistance, capable of withstanding both radial and axial loads.

- Characteristics: High-quality bearings reduce friction and wear, ensuring the drum operates steadily over time. The drive system should also provide consistent power output, preventing jerky or uneven movements during crane operations.

7. Safety Factor

- Selection Standard: The drum design should include an adequate safety factor, typically between 5 and 6 times the rated load. This safety factor accounts for emergency situations, such as wire rope breakage or overload, ensuring that the drum can still operate safely under extreme conditions.

- Characteristics: A higher safety factor enhances the drum’s reliability and resistance to damage. However, this may also increase the drum’s weight and cost. A balance between safety and cost should be considered during the selection process.

8. Corrosion Protection

- Selection Standard: For environments with high humidity, salinity, or chemical exposure, the drum should be treated with corrosion-resistant coatings, such as galvanization, powder coating, or surface painting.

- Characteristics: Corrosion-resistant treatments significantly extend the drum’s lifespan, especially in marine or chemical environments where corrosion is more prevalent.

9. Maintenance and Inspection

- Selection Standard: The drum should be designed for easy maintenance and inspection. It should allow for regular checks on the wire rope’s wear and bearing lubrication to prevent any operational failure.

- Characteristics: A drum that is easy to inspect and maintain helps detect issues such as excessive wire rope wear or bearing damage early, thus preventing equipment failure and ensuring continuous operation.

10. Compliance with Standards

- Selection Standard: The drum’s design and manufacturing should comply with relevant national and international standards, such as ISO 4301 and GB/T 3811. These standards ensure the drum’s quality, performance, and safety.

- Characteristics: A drum that meets these standards has undergone strict testing and certification, guaranteeing its safety and reliability during crane operations.

overhead crane drum Summary:

In conclusion, selecting an overhead crane drum requires a comprehensive evaluation of various factors, including rated load, wire rope capacity, material choice, design, working environment, safety factor, and maintenance ease. By carefully considering these elements, one can ensure smooth, efficient, and safe crane operation, while extending the equipment’s lifespan.