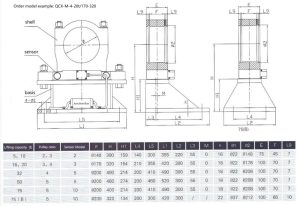

Crane overload limiter

Main parameters:

- Accuracy ≤5%F.S.

- 90% warning, 105% alarm

- 130% immediate control, output a set of relay contacts

- Capacity 10A, 380V

- Power supply voltage AC380V or 220V/50Hz

- Ambient temperature -20~+60℃/90%RH

- Protection level sensor IP65,

- Instrument IP42

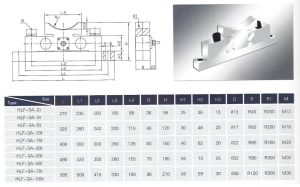

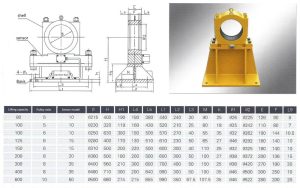

Sensors for large tonnage limiters are generally customized according to user drawings. The series dimensions in the following table are summarized based on the order drawings of major Chinese crane manufacturers for reference when new users order or design non-standard products.

HLF-3A series sensors consist of two parts: sensors and pads. They are mainly installed under the two ends of the fixed pulley shaft of the crane to withstand the pressure generated by the pulley block. Generally, two sensors are used in a group. They are often used in occasions with relatively high measurement accuracy requirements, such as crane electronic scales.