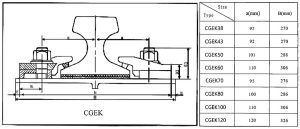

CGEK Rail Clip

Specifications of CGEK Rail Clip

- Models: CGEK38, CGEK43, CGEK50, CGEK60, CGEK70, CGEK80, CGEK100, CGEK120

- Fixing Method: Welded base plate

Features of CGEK Rail Clip

Lateral Adjustment

The CGEK rail clip allows for lateral adjustment, which optimizes the conditions for precise track installation and alignment. This flexibility ensures that the rail system is accurately positioned, facilitating smooth and efficient crane operation.

Reliability in Withstanding Lateral Forces

The clips’ fixed components are designed to reliably withstand the lateral forces generated during crane operations. As a result, they ensure stability, preventing movement and enhancing the overall safety and performance of the crane rail system.

Compact Design

With a narrow and flat structure, these clips offer optimal installation dimensions, making them suitable for cranes both with and without guide wheels. This compact design helps maximize space efficiency and provides ease of installation.

Automatic Locking Mechanism

Thanks to the wedge-shaped design and the interlocking inclined surfaces of the upper and lower clamp plates, the clips automatically lock in place. This automatic locking mechanism simplifies the installation process and ensures that the clips remain securely in position during operation.

Tolerance Control and Contact Durability

The CGEK rail clip effectively accommodates the tolerances of the rail and crane beam, ensuring a precise fit. Moreover, it maintains long-lasting contact between the rail and the base, supported by pre-stressed bases that enhance durability and stability.

Noise Reduction

The innovative design of the CGEK rail clip significantly reduces noise, which contributes to an improved working environment. This feature is particularly beneficial in settings where noise control is crucial to maintain operational efficiency and worker comfort.

High-Strength Materials

The components are manufactured from low-alloy, high-strength structural steel, ensuring enhanced durability and performance. This material choice extends the lifespan of the clips, even under heavy-duty and demanding conditions.

High-Strength Bolts

Equipped with M20, grade 8.8 high-strength bolts, the CGEK rail clip system offers a tightening torque of 220 N·m. Furthermore, it can withstand a maximum lateral force of 120 kN exerted by wheel pressure, ensuring the clips can perform reliably under high loads.

Installation Steps for CGEK Rail Clip

Base Plate Positioning

To begin, place the base plates along the crane rail at 500 mm intervals. Ensure that the base plates are aligned perpendicularly to the rail, with the T-bolt’s center spaced from the rail centerline according to the specified value aaa.

Welding the Base Plates

Next, securely weld the base plates in the determined positions. This ensures that the base plates are firmly fixed to the crane beam, forming a stable foundation for the entire rail system.

Sequential Installation

After welding the base plates, proceed with the sequential installation of the components:

- Position the T-bolts in place.

- Install the components in the following order: top cover plate, flat washer, spring washer, and nut.

- Finally, tighten the T-bolts and adjust the top cover plate as needed to ensure a secure and stable assembly.

By following these detailed steps, the CGEK rail clip system can be efficiently installed, offering a reliable and durable solution for securing crane rails while ensuring smooth operation and longevity. The precise design features and ease of installation make it an excellent choice for demanding industrial applications.