Billet crane clamp

Billet crane clamp,Billet lifting clamp,Billet Clamps,Billet crane clamps manufacturer,billet lifting clamps china supplier,Special Crane Spreader

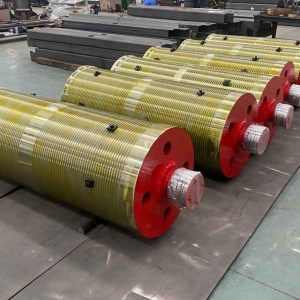

Introduction to Billet Crane Clamp

A billet crane clamp is a specialized lifting device used in the handling and transportation of billets—long, solid metal bars or bars of metal that are typically used as raw materials for further processing in steel and metal industries. The crane clamp is designed to securely grip and lift billets in a safe and efficient manner, ensuring minimal risk of damage during loading, unloading, or transport within the plant or factory.

Main Functions

- Secure Lifting of Billets: The primary function of the billet crane clamp is to securely hold and lift billets, which are often too heavy or awkward to handle manually. The clamp provides a safe means of transferring billets from one location to another, reducing the risk of accidents.

- Efficient Material Handling: In steel mills and metal processing plants, billets are frequently moved between various stages of the production process. The billet crane clamp allows for the quick and efficient handling of these materials, improving overall operational efficiency.

- Prevention of Damage: Billets, being heavy and prone to surface damage, require careful handling during transport. The crane clamp is designed to firmly grip the billets without causing any harm to their surface, preventing scratches, dents, or other forms of damage.

- Versatile Lifting Capacity: Billet crane clamps are usually adjustable, meaning they can handle billets of different sizes and weights. This versatility allows them to be used in various applications within a plant or warehouse, such as during the initial loading of billets or for moving them between different production lines.

Key Structural Components

- Clamp Arms: The clamp arms are the primary components of the crane clamp that make contact with the billet. They are typically made from high-strength steel or alloy to withstand the high forces involved in lifting heavy billets.

- Hydraulic System: Many billet crane clamps feature a hydraulic mechanism that controls the opening and closing of the clamp arms. This system provides the necessary force to grip the billets tightly and release them when necessary. Hydraulic systems allow for more precise control of the clamp’s operation.

- Rotational Mechanism: Some billet crane clamps are equipped with a rotational mechanism that allows them to rotate the billet as needed. This can be particularly useful for repositioning or orienting the billets correctly during transport.

- Lifting Hook: The lifting hook connects the crane clamp to the overhead crane, providing the point of attachment for the lifting operation. This hook allows for easy and quick connection to the crane system.

- Control System: Modern billet crane clamps may come with an integrated control system, allowing operators to adjust the clamping force and operation speed. The control system ensures that the billets are securely held and released without any manual intervention.

Applications

- Steel Mills: Billet crane clamps are commonly used in steel mills where billets are produced and processed. They are used to handle billets during the forging, rolling, or cooling stages.

- Metal Processing Plants: These clamps are also used in plants that handle non-ferrous metals, such as aluminum or copper, where billets are part of the production process.

- Storage and Transport: Billet crane clamps are often employed in warehouses or distribution centers for the handling and storage of billets before they are processed further or shipped out.

- Construction and Heavy Industry: In industries such as construction, the crane clamp can be used to lift and transport metal billets for large-scale infrastructure projects.

Advantages

- Increased Safety: The billet crane clamp improves safety by allowing for the secure lifting and transport of heavy billets without manual handling, reducing the risk of injury.

- Enhanced Efficiency: By automating the process of lifting and moving billets, the crane clamp improves productivity and reduces the time spent on material handling.

- Prevention of Material Damage: The design of the billet crane clamp ensures that billets are lifted without causing damage to their surface, which is crucial in industries where material integrity is important.

- Versatility: Adjustable clamp arms and hydraulic control mechanisms allow the billet crane clamp to handle billets of various sizes and weights, making it adaptable to different industrial environments.

Conclusion

In conclusion, the billet crane clamp is a vital piece of equipment for industries that deal with billets, particularly in steel mills, metal processing plants, and heavy manufacturing sectors. Its ability to securely lift and transport billets without causing damage to the material or risking operator safety makes it an essential tool for efficient and safe operations. The versatility, safety features, and efficiency improvements it offers make it a valuable asset for businesses in the metalworking industry.

Dimensions and parameters

| Lifting capacity (t) |

w (mm) |

h (mm) |

L (mm) |

Maximum dimensions(mm) | |

| W | H | ||||

| 5 | 450-600 | 250 | 800 | 1200 | 1800 |

| 5 | 650-1000 | 250 | 800 | 1500 | 2300 |

| 8 | 150-450 | 250 | 1200 | 2000 | 2400 |

| 8 | 450-600 | 250 | 1200 | 1600 | 2500 |

| 8 | 450-750 | 300 | 1200 | 1600 | 2200 |

| 10 | 450-900 | 300 | 1500 | 1900 | 2600 |

| 10 | 650-1000 | 300 | 1500 | 1600 | 2600 |

| 10 | 700-1100 | 300 | 1500 | 1700 | 2600 |

| 12 | 450-750 | 300 | 2000 | 1800 | 2400 |

| 12 | 235-800 | 300 | 2000 | 2300 | 3000 |

| 16 | 600-1100 | 300 | 2500 | 2400 | 3100 |

| 16 | 850-1250 | 300 | 2500 | 2000 | 3000 |

| 20 | 800-1300 | 300 | 3000 | 2200 | 3400 |

| 20 | 950-1400 | 300 | 3000 | 2500 | 3500 |

| 20 | 1100-1600 | 300 | 3000 | 2400 | 3700 |

| 25 | 1000-1600 | 600 | 3000 | 3000 | 3900 |

| 25 | 1250-1750 | 450 | 3000 | 2800 | 3900 |

| 32 | 700-1350 | 450 | 3000 | 2900 | 4000 |

| 32 | 750-1400 | 450 | 3000 | 2800 | 4200 |

| 32 | 650-1500 | 450 | 3000 | 3400 | 4600 |

| 32 | 900-2150 | 600 | 3000 | 4400 | 6000 |

| 32 | 1000-2300 | 600 | 3000 | 4700 | 6300 |

| 40 | 850-1600 | 450 | 3500 | 3500 | 4900 |

| 40 | 1250-1750 | 450 | 3500 | 3000 | 3000 |

| 40 | 1600-2150 | 450 | 3500 | 3300 | 4300 |

| 50 | 1250-2150 | 450 | 4000 | 4000 | 5600 |

| 50 | 1850-2500 | 450 | 4000 | 3800 | 5000 |

| 50 | 1200-2750 | 750 | 4000 | 5600 | 7600 |

| 63 | 2050-2750 | 600 | 4000 | 4300 | 5800 |

| 80 | 750-1650 | 900 | 4500 | 5300 | 7100 |