Container spreader

Container spreader manufacturers,20ft Container Spreader,Semi Automatic container spreader,40ft Container Lifting Frame,Container spreader

Introduction to Container Spreader

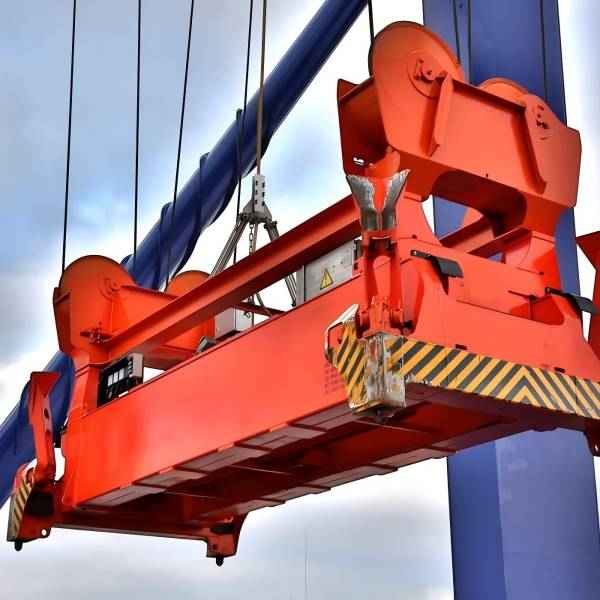

A container spreader is a device specifically designed for lifting, transporting, and precisely placing containers. It is typically used on port cranes, such as quay cranes and gantry cranes. The spreader connects to the crane’s hook or lifting ropes, and it ensures the secure lifting and handling of containers. With its extension and locking mechanisms, the container spreader plays a crucial role in maintaining the stability and safety of containers during the lifting process.

Main Functions

- Container Lifting: The primary function of the container spreader is to lift containers from cargo ships or from port yards and transport them to other locations. It connects to the four corner castings of the container, securing the container in place during the lifting operation.

- Precise Placement: The container spreader ensures the precise placement of containers when moving them from one location to another. This is especially important in port operations where high precision is required for stacking and unloading. The spreader helps prevent containers from tilting or falling during transfer.

- Extension and Adjustment: Most container spreaders are equipped with an extendable feature, allowing them to adjust their width to accommodate different container sizes (such as 20-foot, 40-foot, or 45-foot containers). This adaptability means that the same spreader can handle multiple container sizes, increasing operational efficiency.

- Locking Mechanism: To ensure the container does not slip off during lifting, the container spreader is equipped with a locking mechanism. This can be either automatic or manual, and it securely locks the four corner castings of the container once connected, preventing accidental detachment during the lifting process.

- Improved Efficiency: Container spreaders are designed for quick connection and disconnection, which increases crane operational efficiency. In busy ports, the spreader reduces turnaround time, helping to speed up cargo handling and transportation.

Key Structural Components

- Frame: The frame supports the entire structure of the spreader and is typically made from high-strength steel to handle the weight of the container.

- Hooks or Lifting Rings: These connect the spreader to the crane’s lifting system, facilitating the lifting operation.

- Extendable Arms: The extendable portion of the spreader allows it to adapt to different container sizes.

- Locking Mechanism: This mechanism ensures the secure attachment of the container’s corner castings to the spreader, preventing the container from shifting.

- Control System: Modern container spreaders may feature electronic control systems to manage extension, locking, and other functions, with some even offering remote control capabilities.

Advantages

- Increased Efficiency: The automatic locking system and quick-operating design significantly improve the efficiency of container handling.

- Adaptability to Different Sizes: The extendable arms make the spreader suitable for a wide range of container sizes, providing high versatility.

- High Safety: The locking mechanism ensures that containers remain stable and secure during handling, reducing the risk of accidents.

- Reduced Manual Intervention: Modern container spreaders often come with automated control systems, reducing the need for manual operations and enhancing safety and efficiency.

Conclusion

In conclusion, the container spreader is an essential piece of equipment in port, dock, and other container-handling operations. It provides efficient, safe, and precise lifting and handling of containers. The extendability and locking mechanisms allow it to accommodate different container sizes, making it widely used in container transportation, loading, unloading, and stacking operations worldwide.