Crane Safety brake

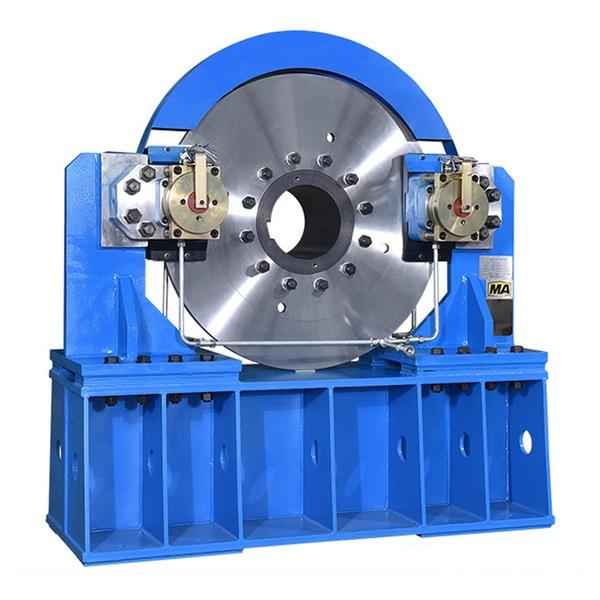

SB Series Crane Safety Brake:

- Product Models: SB50, SB100, SB160, SB250, SB315, SB400, SB500

- Applicable Disc Diameter (mm): 500, 600, 1200, 1800

- Brake Disc Thickness (mm): 30, 36, 40

- Clamping Force F (KN): 50–500

Hydraulic Safety Emergency Brake

The SB series crane safety brake are high-power braking devices specifically designed for low-speed shafts, such as drum shafts. These brakes are widely used for emergency safety braking in medium and large cranes, port handling machinery lifts, and boom tilting mechanisms. Moreover, they are ideal for the operational and emergency safety braking of mining hoists, lift equipment, and high-power inclined belt conveyors. They also serve as essential safety brakes in cable car and cable crane drive mechanisms. In addition, these brakes provide emergency braking for the low-speed shafts of hoist mechanisms in special lifting applications, such as casting cranes.

Main Features of Crane Safety Brake

- Designed with a normally closed structure, these brakes are both safe and reliable. The braking force is applied through a specially designed disc spring, while hydraulic power is used to release the brake (for hydraulic station selection, refer to the hydraulic station catalog).

- Additionally, the brakes come equipped with high-performance, asbestos-free hard friction pads. These pads offer a stable friction coefficient, preventing damage to the brake disc. They are also resistant to water and salt fog (sea spray), ensuring reliable operation in challenging environments.

- The brakes are highly responsive, with short closing (braking) times, ensuring quick reaction in emergency situations.

- To further enhance functionality, optional switches such as release limit and pad wear limit switches are available. These switches provide signal displays or interlock protection, improving overall safety.

- Furthermore, a well-designed sealing structure, along with premium imported seals, ensures effective sealing and extends the brake’s service life.

- Thanks to their flexible installation options, these brakes are easy to use, adjust, and maintain, providing long-term operational efficiency.

Operating Conditions

- Ambient Temperature: These brakes function optimally within a temperature range of -20°C to +50°C.

- Relative Humidity: The brakes are effective when the relative humidity is ≤90%.

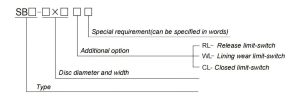

Order Mark

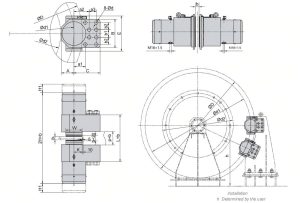

Dimensions and technical data

Technical data of SB series safety brake |

|||||||||||||||||||||

| Type | Clamp force F (KN) |

Release pressure (MPa) |

Releaseoil volume (ml) |

Clearance (mm) |

Friction coefficient | Mounting bolts bolts/performance class/Installation torque |

Weight bracket excluded (kg) |

||||||||||||||

| Static | Dynamic | ||||||||||||||||||||

| SB50 | 50 | 1 | 30 | 1-2 | 0.4 | 0.36 | 8-M20、10.9、550±10 | 90 | |||||||||||||

| SB100 | 100 | 12 | 50 | 1-2 | 0.4 | 0.36 | 8-M24、10.9、950±10 | 150 | |||||||||||||

| SB160 | 160 | 12 | 70 | 1-2 | 0.4 | 0.36 | 8-M30、10.9、1900±20 | 310 | |||||||||||||

| SB250 | 250 | 16.5 | 95 | 1-2 | 0.4 | 0.36 | 8-M36、10.9、3300±40 | 452 | |||||||||||||

| SB315 | 315 | 17 | 115 | 1-2 | 0.4 | 0.36 | 8-M36、10.9、3300±40 | 672 | |||||||||||||

| SB400 | 400 | 16.5 | 170 | 1-2 | 0.4 | 0.36 | 8-M48、10.9、7500±100 | 1100 | |||||||||||||

Brake torque Nm=F×μ×d1 |

|||||||||||||||||||||

| Type | A | a1 | a2 | a3 | b1 | b2 | B | C | d | k | P | L | E | W | H | H1 | |||||

| SB50 | 77 | 77 | 90 | 38 | 38 | 38 | 154 | 150 | 20.5 | 56 | 102 | 300 | 240 | 110 | 310 | 80 | |||||

| SB100 | 95 | 95 | 105 | 45 | 55 | 45 | 190 | 180 | 25 | 71 | 102 | 348 | 286 | 140 | 360 | 85 | |||||

| SB160 | 110 | 120 | 135 | 65 | 70 | 65 | 260 | 235 | 31 | 87 | 106 | 412 | 370 | 170 | 410 | 95 | |||||

| SB250 | 130 | 120 | 160 | 75 | 80 | 75 | 300 | 275 | 37 | 87 | 106 | 456 | 370 | 170 | 470 | 110 | |||||

| SB315 | 140 | 175 | 205 | 85 | 90 | 82.5 | 335 | 330 | 37 | 137 | 106 | 476 | 410 | 270 | 500 | 110 | |||||

| SB400 | 170 | 180 | 220 | 120 | 110 | 110 | 440 | 420 | 50 | 137 | 142 | 602 | 546 | 270 | 560 | 115 | |||||

| SB500 | 170 | 180 | 220 | 120 | 110 | 110 | 440 | 420 | 50 | 137 | 142 | 682 | 542 | 270 | 600 | 115 | |||||

Relative Dimensions of brake disc(mm) |

|||||||||||||||||||||

| Type | b | D | d1 | d2 max | |||||||||||||||||

| SB50 | 30 | 36 | 40 | ≥500 | D-120 | D-300 | |||||||||||||||

| SB100 | 30 | 36 | 40 | ≥500 | D-150 | D-380 | |||||||||||||||

| SB160 | 30 | 36 | 40 | ≥600 | D-180 | D-440 | |||||||||||||||

| SB250 | 30 | 36 | 40 | ≥600 | D-180 | D-480 | |||||||||||||||

| SB315 | 30 | 36 | 40 | ≥1200 | D-280 | D-600 | |||||||||||||||

| SB400 | 30 | 36 | 40 | ≥1800 | D-280 | D-660 | |||||||||||||||

| SB500 | 30 | 36 | 40 | ≥1800 | D-280 | D-660 | |||||||||||||||

| d1=the theoretical friction diameter, d2=max .allowable drum or hub diameter D:For other disc diameters please contact us |

|||||||||||||||||||||