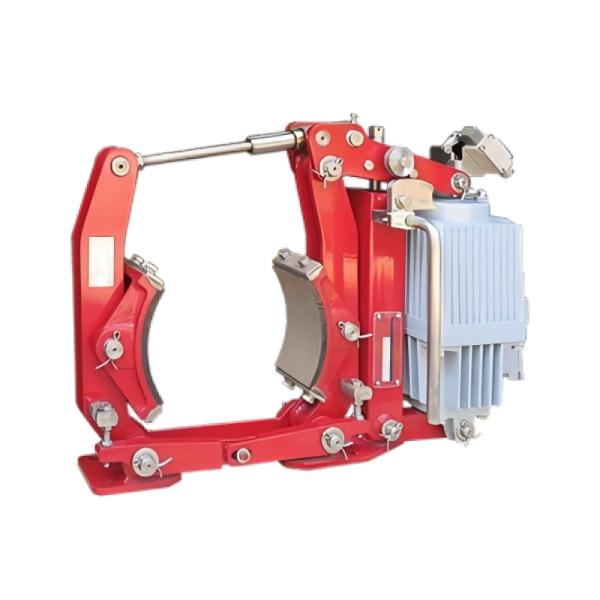

Electro hydraulic drum brake

YWZ4 Electro hydraulic drum brakes Models:

- Product Models: YWZ4-160/22, YWZ4-200/22 (30), YWZ4-250/30 (50), YWZ4-300/30 (50, 80), YWZ4-315/30 (50, 80), YWZ4-400/50 (80, 125), YWZ4-500/80 (125, 200), YWZ4-630/125 (200, 300), YWZ4-710/200 (300), YWZ4-8000/300

- Brake Wheel Diameter (mm): 160, 200, 250, 300, 315, 400, 500, 560, 630, 710, 800

- Braking Torque (Nm): 80~12500

Electric Hydraulic Drum Brake

The YWZ4 Electro Hydraulic Drum Brake is widely used for deceleration and parking (holding) braking. Specifically, they are essential in various lifting and transport mechanisms, port loading and unloading operations, metallurgical equipment, mining machinery, and construction machinery.

Electro hydraulic drum brake Main Features

To enhance performance, the brakes incorporate an interlocking equal clearance device and an automatic alignment device for the brake shoes. These devices ensure that the clearance on both sides of the brake shoes remains equal without requiring manual adjustment. Consequently, they effectively prevent one side’s brake pad from sticking to the brake wheel due to uneven clearance.

Additionally, manufacturers design the brake pad with a clamped integrally molded structure. This design makes replacement straightforward and efficient. Users can choose from a range of materials, including semi-metal (asbestos-free) hard and semi-hard options, as well as soft (asbestos-free) varieties, to suit their specific needs.

For improved durability, engineers equip all main pivot points with self-lubricating bearings. This feature significantly increases transmission efficiency and extends the brake’s service life.

Furthermore, the brake spring is strategically positioned inside a square tube and paired with a scale. This arrangement allows users to easily read the braking torque value, thus eliminating the need for complex measurements or calculations.

To complement these features, the matched series of thrusters provide high responsiveness and exceptional durability, ensuring reliable operation under various conditions.

Operating Conditions

- Ambient Temperature: The brakes operate effectively in environments with temperatures ranging from -20℃ to +50℃.

- Relative Humidity: They perform reliably when the relative humidity is ≤90%.

- Voltage Level: The brakes are designed to function with three-phase AC 380V/50Hz.

- Duty Cycle: They support both continuous operation (S1) and intermittent operation (S3-60%), with a maximum operation frequency of ≤1200 times per hour.

Additional Devices

To further enhance usability and safety, the YWZ4 Electro Hydraulic Drum Brakes offer the following optional devices:

- Manual Release Device: Users can manually release the brake when necessary.

- Brake Lining Wear Limit Switch: This device signals when the brake lining has reached its wear limit. (Note: Applicable only to brakes equipped with an automatic compensation device.)

- Release (Brake Open) Limit Switch: This switch provides an indication to confirm that the brake has been released correctly.

- Thruster with Lowering Delay Valve: When equipped with this feature, the brake can achieve delayed closure to meet specific operational requirements.

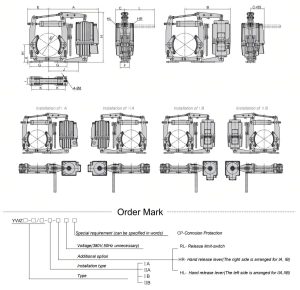

YWZ4 Electro hydraulic drum brake Technical Specifications and Installation Dimensions

| Brake type | Thruster type | Brake torque (N.m) |

Dimensions (mm) | Weight (kg) |

|||||||||||||||||

| D | h1 | k | i | d | n | b | F | G | J | E | H | A | B | L | C | ||||||

| A | B | A | B | ||||||||||||||||||

| YWZ4-160/22 | YTD220-50 | 80~160 | 160 | 132 | 130 | 55 | 14 | 6 | 65 | 90 | 150 | 210 | 165 | 390 | 415 | 380 | 80 | 120 | 200 | 80 | 25 |

| YWZ4-200/22 | YTD220-50 | 100~200 | 200 | 160 | 145 | 55 | 14 | 8 | 80 | 90 | 165 | 265 | 195 | 470 | 440 | 405 | 80 | 120 | 260 | 80 | 38 |

| YWZ4-200/30 | YTD300-50 | 140~280 | 245 | 39 | |||||||||||||||||

| YWZ4-250/30 | YTD300-50 | 160~315 | 250 | 190 | 180 | 65 | 18 | 10 | 100 | 100 | 200 | 275 | 225 | 500 | 490 | 455 | 80 | 120 | 260 | 80 | 47 |

| YWZ4-250/50 | YTD500-60 | 250~500 | 550 | 550 | 490 | 97 | 157 | 320 | 97 | 61 | |||||||||||

| YWZ4-300/30 | YTD300-50 | 160~315 | 300 | 225 | 220 | 80 | 18 | 10 | 125 | 110 | 245 | 358 | 275 | 585 | 550 | 510 | 80 | 120 | 260 | 80 | 74 |

| YWZ4-300/50 | YTD500-60 | 250~500 | 590 | 530 | 97 | 157 | 340 | 97 | 86 | ||||||||||||

| YWZ4-300/80 | YTD800-60 | 500~1000 | 88 | ||||||||||||||||||

| YWZ4-315/30 | YTD300-50 | 160~315 | 315 | 225 | 220 | 80 | 18 | 10 | 125 | 110 | 245 | 358 | 275 | 585 | 570 | 510 | 80 | 120 | 260 | 80 | 74 |

| YWZ4-315/50 | YTD500-60 | 250~500 | 590 | 530 | 97 | 157 | 340 | 97 | 86 | ||||||||||||

| YWZ4-315/80 | YTD800-60 | 500~1000 | 88 | ||||||||||||||||||

| YWZ4-400/50 | YTD500-60 | 315~630 | 400 | 280 | 270 | 100 | 22 | 12 | 160 | 140 | 300 | 420 | 350 | 705 | 625 | 565 | 97 | 157 | 450 | 97 | 108 |

| YWZ4-400/80 | YTD800-60 | 630~1250 | 110 | ||||||||||||||||||

| YWZ4-400/125 | YTD1250-60 | 900~1800 | 770 | 610 | 580 | 120 | 150 | 120 | 133 | ||||||||||||

| YWZ4-500/80 | YTD800-60 | 800~1600 | 500 | 335 | 325 | 130 | 22 | 16 | 200 | 180 | 365 | 484 | 395 | 835 | 740 | 680 | 97 | 157 | 450 | 97 | 202 |

| YWZ4-500/125 | YTD1250-60 | 1125~2250 | 410 | 850 | 730 | 700 | 120 | 150 | 120 | 212 | |||||||||||

| YWZ4-500/200 | YTD2000-60 | 1600~3150 | 212 | ||||||||||||||||||

| YWZ4-630/125 | YTD1250-120 | 1400~2800 | 630 | 425 | 400 | 170 | 27 | 20 | 250 | 220 | 450 | 590 | 505 | 1025 | 840 | 810 | 120 | 150 | 450 | 120 | 309 |

| YWZ4-630/200 | YTD2000-120 | 2250~4500 | 310 | ||||||||||||||||||

| YWZ4-630/300 | YTD3000-120 | 3550~7100 | 315 | ||||||||||||||||||

| YWZ4-710/200 | YTD2000-120 | 2500~5000 | 710 | 475 | 450 | 190 | 27 | 22 | 280 | 240 | 500 | 705 | 565 | 1170 | 1050 | 1020 | 120 | 150 | 450 | 120 | 455 |

| YWZ4-710/300 | YTD3000-120 | 4000~8000 | 460 | ||||||||||||||||||

| YWZ4-800/300 | YTD3000-120 | 6300~12500 | 800 | 530 | 520 | 210 | 27 | 28 | 320 | 280 | 570 | 860 | 710 | 1410 | 1085 | 1060 | 120 | 150 | 450 | 120 | 652 |