F Series Gear Motor

F Series Gear Motor Specifications

- Models: F..03, F..04, F..05, F..06, F..07, F..08, F..09, F..10, F..12, F..15, F..16, F..18

- Speed Ratio: 3.77 to 267.43

- Power Range: 0.12, 0.18, 0.25, 0.37, 0.55, 0.75, 1.1, 1.5, 2.2, 3, 4, 5.5, 7.5, 11, 15, 18.5, 22, 30, 37, 45, 55, 75, 90, 110, 132, 160, 200 kW

- Structural Types: FA, FAF, F, FH

- Output Torque: 200 Nm to 18,000 Nm

Performance Characteristics

The F Series Gear Motor, K Series Gear Motor, and R Series Gear Motor are not only compact but also powerful, delivering high torque despite their small size. These gear motors are designed and manufactured using a modular combination system. As a result, they offer a wide range of motor combinations, mounting configurations, and structural options. Furthermore, the finely graded transmission ratios enable them to adapt seamlessly to diverse operating conditions, achieving efficient electromechanical integration.

In particular, the F, K, and R series gear reducers utilize a modular unit design that streamlines the manufacturing process. This approach significantly reduces the variety of parts and inventory levels, thereby shortening delivery times. Moreover, these gear motors excel with their high transmission efficiency, low energy consumption, and outstanding overall performance, making them a standout choice in their category.

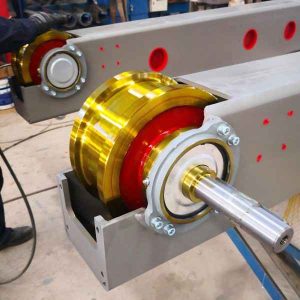

The gear motors incorporate a high-rigidity cast iron housing reinforced with ribs for added strength. Additionally, manufacturers craft the gears from high-quality alloy steel, applying a carburizing and quenching hardening process. They follow this with precision grinding, which ensures smooth transmission, low noise, high load capacity, minimal temperature rise, and an extended service life.

Thanks to their exceptional versatility, these gear motors are widely applied across various industries. For example, they are indispensable in lifting equipment, light industry, escalators, automated storage systems, construction machinery, steel and metallurgy, papermaking, and wood panel production. Additionally, they are frequently used in automobile manufacturing, tobacco machinery, water conservation projects, printing and packaging, pharmaceuticals, textiles, construction materials, logistics, feed machinery, and environmental protection.

Before shipping, manufacturers leave these gear reducers without oil to ensure safe transportation. Therefore, users are advised to add N220 medium-pressure industrial gear oil before operating the motors to optimize their performance.

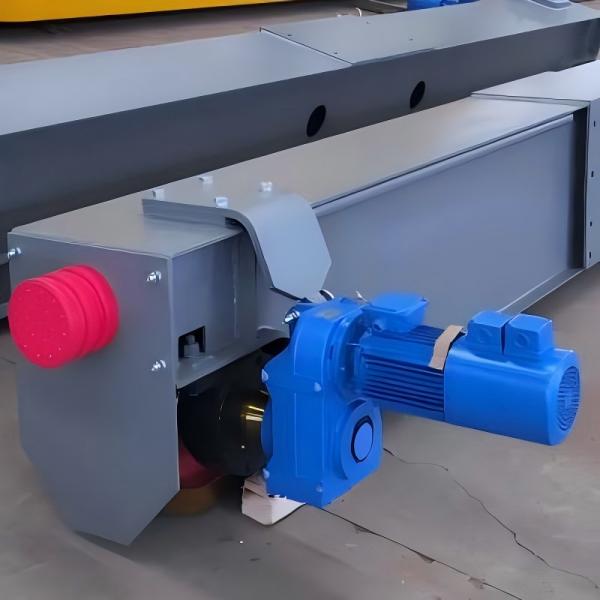

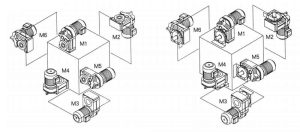

Structure and Configuration

Installation Forms

Motor Junction Box Position

F Series Gear Motor Speed Ratio Range and Maximum Torque

| Type | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 | 12 | 15 |

| Structural form | FA,FAF,F,FH | |||||||||

| Gear ratio | 3.77~

128.51 |

4.99~

190.76 |

5.18~

199.7 |

3.97~

228.99 |

4.28~

281.71 |

4.12~

270.68 |

4.57~

276.77 |

6.22~

254.4 |

4.68~

170.83 |

11.92~

267.43 |

| Maximum Torque

N.m |

200 | 400 | 600 | 820 | 1500 | 3000 | 4300 | 7840 | 12000 | 18000 |