Cardan Shaft Coupling

Cardan Shaft Coupling Parameters:

- Maximum Allowable Torque: 2.5 kN.m to 1000 kN.m

- Shaft Deflection Angle: ≤ 25°, ≤ 15°

- Flange Diameter: ∅100 to ∅550

- Length: 405 mm to 2300 mm

- Length Extension Range: 55 mm to 240 mm

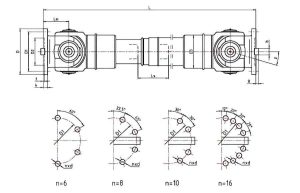

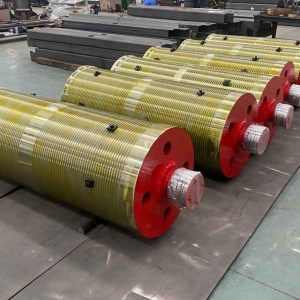

A Cardan Shaft Coupling (also known as a Universal Joint Coupling) is a mechanical component used to connect two shafts and transmit torque. It consists of a cross-shaped shaft, two yokes, and two shaft sleeves. The coupling transmits power through the rotation of the cross shaft and is widely used in power transmission systems that require the accommodation of significant angular misalignment.

Cardan Shaft Coupling Main Features:

- Structure: The Cardan shaft coupling is primarily composed of four basic parts: two yokes, a cross shaft, and two shaft sleeves. The yokes are connected to the cross shaft via bearings, while the shaft sleeves are connected to the working shafts. The cross shaft connects the two yokes at each end, enabling power transmission.

- Working Principle: The Cardan shaft coupling transmits torque through the engagement of the cross shaft with the yokes. Its design allows it to operate even when there is some angular misalignment between the shafts. As the cross shaft rotates, the power is effectively transferred through the yokes and shaft sleeves.

- Applications: The Cardan shaft coupling is mainly used in systems that require high torque transmission and can accommodate certain angular misalignments. Common applications include automobiles, agricultural machinery, conveyor systems, wind turbines, and various other industrial devices.

- Design Advantages: Due to its ability to tolerate significant angular misalignment, the Cardan shaft coupling is particularly suitable for applications where the drive shafts are not perfectly aligned, allowing it to function smoothly even at higher angles of misalignment.

Advantages:

- Good Adaptability: The Cardan shaft coupling can accommodate axial, radial, and angular misalignment, making it ideal for situations where shafts are not perfectly aligned.

- High Torque Transmission Capacity: The coupling can handle substantial torque, making it suitable for high-load, heavy-duty environments.

- Simple and Reliable: The structure of the Cardan shaft coupling is relatively simple, making it easy to use and maintain while ensuring high reliability.

Disadvantages:

- Efficiency Loss: When operating at large angles, the Cardan shaft coupling may experience some efficiency loss, mainly due to the power transmission process.

- Noise and Vibration: Due to the engagement between the yokes and the cross shaft, the Cardan shaft coupling may produce noise and vibration, especially when operating at high speeds.

Conclusion:

The Cardan shaft coupling is a highly adaptable coupling with strong torque transmission capability, commonly used in automobiles, agricultural machinery, and other power transmission systems that require angular compensation. While it offers advantages such as simplicity, high reliability, and high load capacity, it may experience efficiency loss and generate noise and vibration when operating at high angles of misalignment.

SWC-type Cross Shaft Universal Coupling basic parameters and main dimensions

| Type | Rotation diameter D (mm) |

Nominal torque Tn (KN.m) |

Fatigue torque Tf (KN.m) |

Axis angle β (°) |

Scalable capacity Ls (mm) |

Size (mm) | Moment of Inertia (kg/m²) |

Weight (kg) |

|||||||||||

| Lmin | D1(js11) | D2 (H7) |

D3 | Lm | n×∅d | k | t | b (h9) |

g | Lmin | Increase 100mm |

Lmin | Increase 100mm |

||||||

| SWC100BH | 100 | 2.5 | 1.25 | ≤25 | 55 | 405 | 84 | 57 | 60 | 55 | 6×∅9 | 7 | 2.5 | / | / | 0.004 | 0.0002 | 6.1 | 0.35 |

| SWC120BH | 120 | 5 | 2.5 | ≤25 | 80 | 485 | 102 | 75 | 70 | 65 | 8×∅11 | 8 | 2.5 | / | / | 0.001 | 0.0004 | 10.8 | 0.55 |

| SWC150BH | 150 | 10 | 5 | ≤25 | 80 | 590 | 130 | 90 | 89 | 80 | 8×∅13 | 10 | 3 | / | / | 0.042 | 0.0016 | 24.5 | 0.85 |

| SWC180BH | 180 | 22.4 | 11.2 | ≤15 | 100 | 840 | 155 | 105 | 114 | 110 | 8×∅17 | 17 | 5 | 24 | 7 | 0.175 | 0.007 | 70 | 2.8 |

| SWC200BH | 200 | 36 | 18 | ≤15 | 110 | 860 | 170 | 120 | 133 | 115 | 8×∅17 | 17 | 5 | 28 | 8 | 0.314 | 0.013 | 98 | 3.7 |

| SWC225BH | 225 | 56 | 28 | ≤15 | 140 | 920 | 196 | 135 | 152 | 120 | 8×∅17 | 20 | 5 | 32 | 9 | 0.538 | 0.023 | 122 | 4.9 |

| SWC250BH | 250 | 80 | 40 | ≤15 | 140 | 1035 | 218 | 150 | 168 | 140 | 8×∅19 | 25 | 6 | 40 | 12.5 | 0.966 | 0.028 | 172 | 5.3 |

| SWC280BH | 285 | 120 | 58 | ≤15 | 140 | 1190 | 245 | 170 | 194 | 160 | 8×∅21 | 27 | 7 | 40 | 15 | 2.011 | 0.051 | 263 | 6.3 |

| SWC315BH | 315 | 160 | 80 | ≤15 | 140 | 1315 | 280 | 185 | 219 | 180 | 10×∅23 | 32 | 8 | 40 | 15 | 3.605 | 0.008 | 382 | 8 |

| SWC350BH | 350 | 225 | 110 | ≤15 | 150 | 1440 | 310 | 210 | 245 | 194 | 10×∅23 | 35 | 8 | 50 | 16 | 5.316 | 0.146 | 532 | 11.5 |

| SWC390BH | 390 | 320 | 160 | ≤15 | 170 | 1590 | 345 | 235 | 267 | 215 | 10×∅25 | 40 | 8 | 70 | 18 | 12.16 | 0.222 | 738 | 15 |

| SWC440BH | 440 | 500 | 250 | ≤15 | 190 | 1875 | 390 | 255 | 325 | 260 | 16×∅28 | 42 | 10 | 80 | 20 | 21.42 | 0.474 | 1190 | 21.7 |

| SWC490BH | 490 | 700 | 350 | ≤15 | 190 | 1985 | 435 | 275 | 351 | 270 | 16×∅31 | 47 | 12 | 90 | 22.5 | 34.1 | 0.69 | 1542 | 27.3 |

| SWC550BH | 550 | 1000 | 500 | ≤15 | 240 | 2300 | 492 | 320 | 426 | 305 | 16×∅31 | 50 | 12 | 100 | 22.5 | 68.92 | 1.357 | 2380 | 34 |