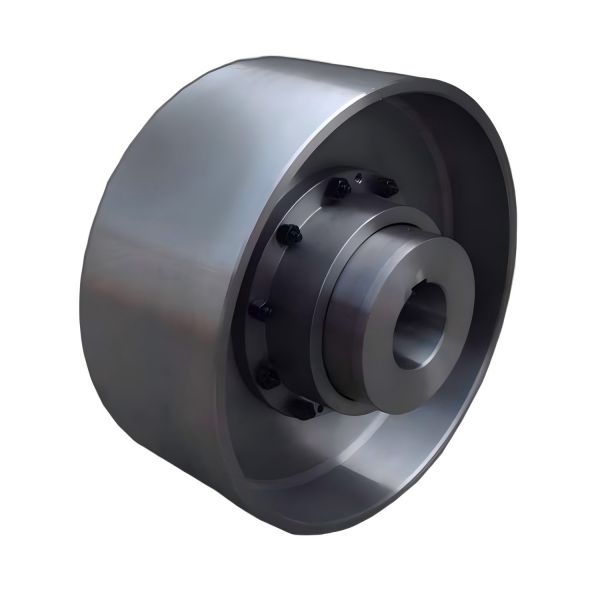

Brake wheel coupling

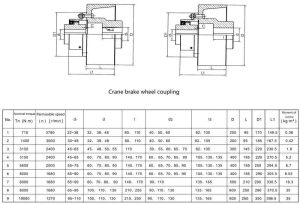

Brake Wheel Coupling Parameters:

- Maximum Allowable Torque: 630 Nm to 125,000 Nm

- Maximum Speed: 4000 rpm to 950 rpm

- Brake Wheel Diameter: ∅160, ∅200, ∅250, ∅300, ∅315, ∅400, ∅500, ∅600, ∅630, ∅700, ∅800

- Coupling Material: ZG430-640, 45 steel

- Coupling Type: Brake wheel with half-tooth coupling

- Custom Options: You can provide your own drawings, and we will manufacture according to the specified dimensions.